In modern winemaking, precision, hygiene, and consistency are everything. Compared with traditional materials such as oak, plastic, or concrete, stainless steel fermentation tanks give winemakers control over every parameter — from temperature to oxygen exposure.

At METO, we design and manufacture high-performance stainless steel wine fermentation tanks that help wineries achieve stable quality, efficiency, and long-term reliability.

Why Stainless Steel Wins in Wine Fermentation

✅ Precise Temperature Control

- Cooling jackets and insulation ensure ideal fermentation temperatures.

- Prevents heat spikes that damage yeast and aroma compounds.

✅ Hygienic and Easy to Clean

- Smooth, non-porous 304/316L stainless surfaces reduce bacterial growth.

- Integrated CIP (clean-in-place) systems simplify sanitation.

✅ Flavor Neutrality

- Stainless steel keeps the wine’s fruit purity intact.

- No unwanted oak or oxidation influence — perfect for clean, crisp profiles.

✅ Durability and Investment Value

- Resistant to corrosion and wear.

- Long lifespan = lower total cost of ownership.

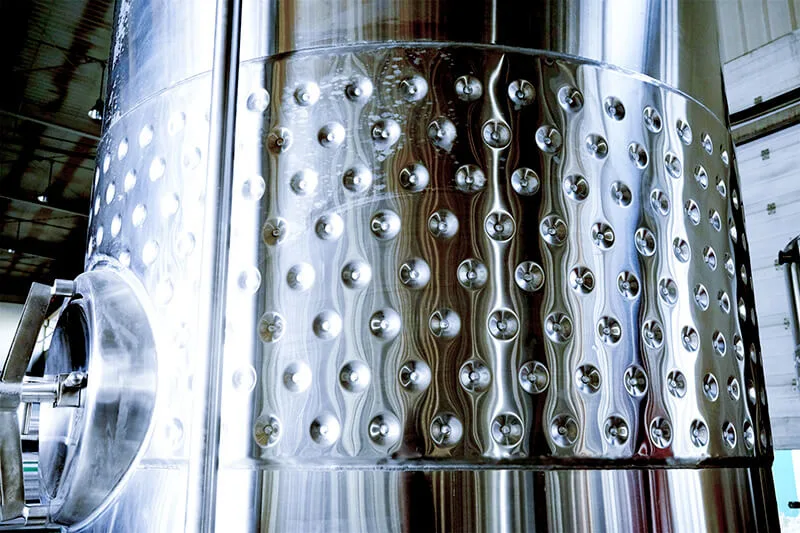

METO Tank Design Features

Every METO wine fermentation tank follows strict engineering standards:

| Feature | Benefit |

|---|---|

| 304/316L stainless steel | High corrosion resistance |

| Mirror-polished interior (Ra ≤ 0.8 µm) | Prevents microbial adhesion |

| Welded, seamless inner structure | No hidden residues |

| Multi-zone cooling jackets | Precise temperature distribution |

| Cone bottom ≥ 60° | Easy lees and sediment removal |

| Inert gas port (N₂/CO₂) | Reduces oxidation risk |

| Sampling valve, racking arm, manway | Operator-friendly & safe |

Temperature & Oxygen Management

During active fermentation, yeast metabolism releases heat rapidly. Without proper cooling, temperature may rise and cause aroma loss or stuck fermentation.

METO’s tanks solve this through:

- Multi-zone cooling jackets

- Optional internal coils

- Real-time temperature sensors and control valves

Additionally, inert gas blanketing systems (CO₂ / N₂) prevent oxidation and volatile acidity.

Easy Cleaning and Maintenance

A typical cleaning protocol includes:

- Hot water rinse

- Alkaline wash

- Acid neutralization / passivation

- Rinse and nitrogen purge

Regular passivation (citric or nitric acid) maintains the chromium oxide layer, preventing corrosion and prolonging tank life.

Conclusion

If your winery values repeatable quality and modern efficiency, a METO stainless steel wine fermentation tank is your best partner. It provides:

- Stable fermentation conditions

- Pure, clean flavor expression

- Efficient cleaning and long service life

Contact METO today to customize your ideal tank configuration and elevate your winemaking process.

If you are also interested in our Stainless Steel Tanks , please feel free to contact us Meto Equipment.