项目详情:

地点:中国

随着精酿啤酒市场的快速增长,啤酒厂越来越需要容量更大、效率更高的酿造系统。本项目采用的 5000 升啤酒酿造设备不仅具有高产能和高效率,还集成了自动化、智能控制和多功能设计,可实现多样化生产。

该啤酒厂的单批次生产能力为 5KL,每天可生产 4-5 批啤酒,年产量达 9000 吨。该系统旨在满足中大型啤酒厂和地区啤酒市场的需求。

5000 升酿酒设备的主要配置

1.铣削系统

- 干法制粉技术包括麦芽提升系统、干法破碎机和灵活的输送系统。

- 生产能力:每小时 3000 公斤麦芽。

- 结合醪水混合系统,提高产量和酿造效率。

2.酿酒房系统(5000 升 4 容器)

- 构成:醪槽,烧煮槽,反应釜,漩涡池。

- 生产能力:每批 5KL,每天 4-5 批。

- 配备气动废谷系统和先进的自动化设备。

- 优点效率高、运行灵活、可扩展,便于未来扩展。

3.发酵系统

- 配置:5T、10T 和 20T 发酵罐和鲜啤酒罐。

- 年产量:约 9000 吨。

- 前发酵走廊布局,包括麦汁、啤酒供应、CIP、压缩空气、CO₂ 和排水等管道。

- 作用精确控制温度和时间,确保啤酒风味、香气和酒体的稳定性。

4. 服务 水箱

- 配置:20 吨乙二醇水箱、20 吨纯水箱、20 吨热水箱、20 吨带泵酿造水箱。

- 功能确保为酿造和 CIP 提供恒温恒压的稳定供水。

5.冷却系统

- 配置:20 吨乙二醇水箱、30HP 冷却器和管道。

- 功能精确控温,用于麦汁冷却、发酵和冷藏,确保酵母活力和啤酒质量。

6.CIP 清洁系统

- 配置:2T 碱罐、2T 酸罐、2T 消毒罐、2T 热水罐、泵和管道。

- 功能:全自动清洗和消毒,确保酿造条件卫生。

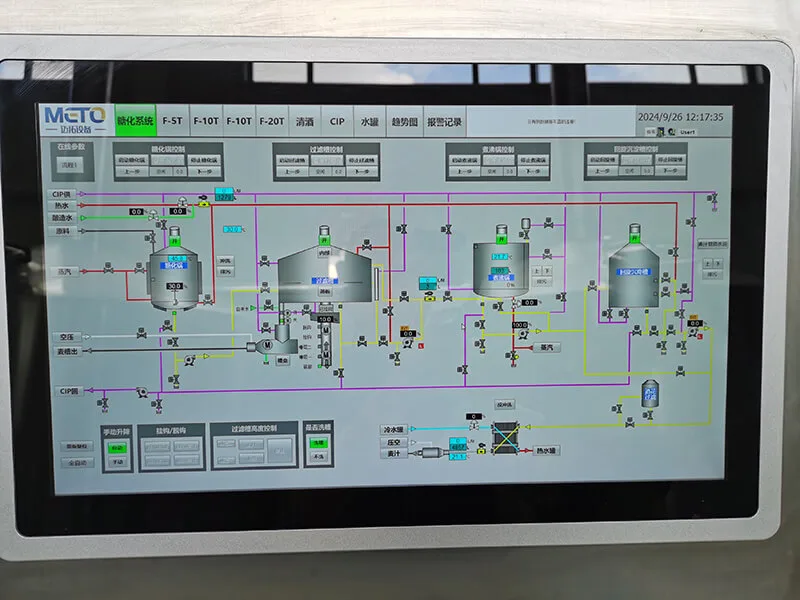

7.控制系统

- 西门子 1500 系列 PLC + WINCC SCADA 系统。

- 两个独立的控制站,用于控制酿酒车间和发酵系统。

- 功能全过程自动化、参数跟踪、实时监控和稳定的啤酒质量。

8.辅助管道系统

- 包括麦汁管线、啤酒管线、上架管线、酵母排放管线、CIP、压缩空气和 CO₂ 管线。

9.酵母分离机和闪蒸巴氏杀菌系统

- 能力:5 吨/小时。

- 与 PLC 集成,用于从澄清到巴氏杀菌的连续无菌啤酒生产。

10.1000 升蒸馏设备

- 技术:将 19 世纪的蒸汽萃取与现代精密工程相结合。

- 应用:生产啤酒烈酒、杜松子酒、威士忌和其他蒸馏饮料。

- 组件:蒸馏釜、蒸馏柱、杜松子酒篮、冷凝器。

- 连续蒸馏,效率高,酒精纯度高。

- 铜柱可去除硫化物,提高香气和纯度。

- 用于灵活生产杜松子酒的杜松子酒篮。

5000 升酿酒厂交钥匙系统设备展示

5000 升交钥匙系统生产标准

- 5000L 酿酒设备 适用于结构新颖、外形美观的啤酒厂

- 所有结构均由 SUS 304 食品级不锈钢制成,所有管道均由 SUS304 不锈钢制成。

- 所有罐体都配有数据板,包括测试数据和序列号

- 所有储油罐都将在无损检测室进行测试和检查,以便进行施工和质量控制检查

- 所有夹克都将进行水压试验,试验压力:0.4 兆帕(4 巴),工作压力:0.2 兆帕(2 巴)

- 所有水箱在离开 MICET 工厂前都将进行 48 小时的压力测试;

- 所有焊缝都使用激光焊接夹具进行焊接,以确保形状一致,并经过酸洗和钝化处理。

- 所有水箱内壁都经过镜面抛光,Ra 0.4um。

5000 升酿造系统的优势

高容量和高效率 - 每批 5KL,每天 4-5 批,每年 9000 吨。

自动化与智能化 - 西门子 PLC,具有全流程自动化、实时监控和数据跟踪功能。

多功能设计 - 能够酿造啤酒和生产烈酒,扩大产品组合。

质量保证 - 先进的冷却和 CIP 系统可确保稳定的发酵、酵母活力和稳定的啤酒质量。

模块化和可扩展 - 系统设计灵活,可轻松扩展,以满足未来生产增长的需要。

如果您对我们的酿酒设备感兴趣,请随时联系我们。 联系我们 梅托设备。我们将根据您的要求推荐最合适的酿酒设备,并为您提供最全面、最优质的服务。