Detalhe do projeto:

Localização:China

Com o rápido crescimento do mercado da cerveja artesanal, as cervejeiras necessitam cada vez mais de sistemas de fabrico de cerveja de maior capacidade e mais eficientes. Este projeto apresenta uma configuração de equipamento de cervejaria de 5000L que não só proporciona uma elevada capacidade e eficiência, como também integra automação, controlo inteligente e design multifuncional para uma produção diversificada.

A sala de brassagem tem uma capacidade de 5KL para um único lote, permitindo 4-5 lotes por dia e uma produção anual de 9.000 toneladas. Este sistema foi concebido para satisfazer as exigências das cervejeiras de média a grande dimensão e dos mercados regionais de cerveja.

A configuração principal do equipamento da fábrica de cerveja 5000L

1. Sistema de fresagem

- Tecnologia de moagem a seco com sistema de elevação do malte, triturador a seco e sistema de transporte flexível.

- Capacidade: 3000 kg de malte por hora.

- Combinado com um sistema de mistura de mosto e água para aumentar o rendimento e a eficiência da produção de cerveja.

2. Sistema de sala de brassagem (5000L 4 vasos)

- Composição: Tina de brassagem, tina de Lauter, caldeira, hidromassagem.

- Capacidade: 5KL por lote, 4-5 lotes por dia.

- Equipado com sistema pneumático de grãos usados e automação avançada.

- Vantagens: Alta eficiência, operação flexível e escalabilidade para expansão futura.

3. Sistema de fermentação

- Configuração: Tanques de fermentação 5T, 10T e 20T e tanques de cerveja clara.

- Capacidade anual: cerca de 9.000 toneladas.

- Disposição do corredor de fermentação frontal com condutas para mosto, fornecimento de cerveja, CIP, ar comprimido, CO₂ e drenagem.

- Função: Controla com precisão a temperatura e o tempo, garantindo a estabilidade do sabor, do aroma e do corpo da cerveja.

4. Serviço Depósitos de água

- Configuração: 20T tanque de água glicolada, 20T tanque de água pura, 20T tanque de água quente, 20T tanque de água para cerveja com bombas.

- Função: Assegura um abastecimento de água estável para a produção de cerveja e CIP com temperatura e pressão constantes.

5. Sistema de arrefecimento

- Configuração: tanque de água glicolada de 20T, refrigerador de 30HP e tubagens.

- Função: Controlo preciso da temperatura para arrefecimento do mosto, fermentação e armazenamento a frio, garantindo a vitalidade da levedura e a qualidade da cerveja.

6. Sistema de limpeza CIP

- Configuração: tanque cáustico 2T, tanque ácido 2T, tanque desinfetante 2T, tanque de água quente 2T, bombas e tubagens.

- Função: Limpeza e esterilização totalmente automatizadas, assegurando condições de fabrico sanitárias.

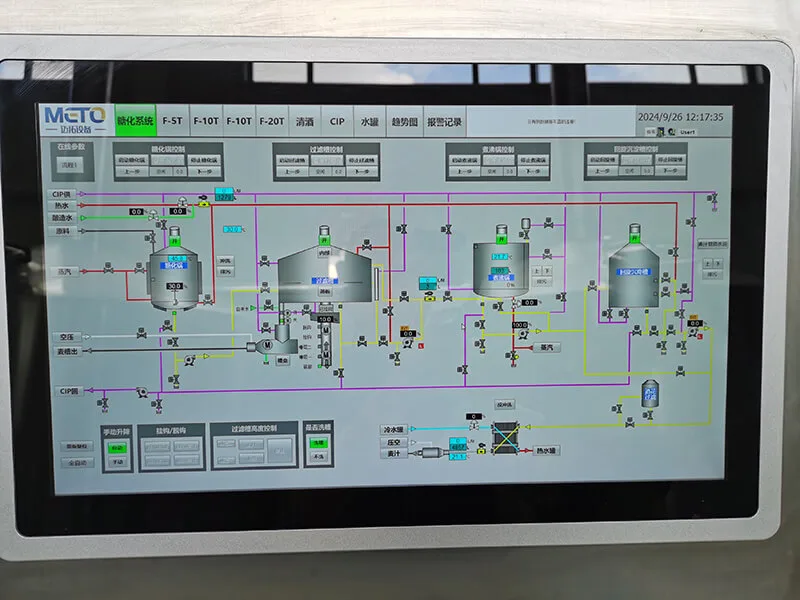

7. Sistema de controlo

- PLC Siemens série 1500 + sistema WINCC SCADA.

- Duas estações de controlo independentes para a sala de brassagem e o sistema de fermentação.

- Função: Automatização total do processo, controlo de parâmetros, monitorização em tempo real e qualidade consistente da cerveja.

8. Sistema de condutas auxiliares

- Inclui tubagem de mosto, tubagem de cerveja, tubagem de racking, tubagem de descarga de levedura, CIP, ar comprimido e tubagens de CO₂.

9. Máquina de Separação de Levedura e Sistema de Pasteurização Flash

- Capacidade: 5 toneladas/hora.

- Integrada com PLC para produção contínua e asséptica de cerveja, desde a clarificação até à pasteurização.

10. Equipamento de destilação 1000L

- Tecnologia: Combina a extração a vapor do século XIX com a moderna engenharia de precisão.

- Aplicações: Produz aguardente de cerveja, gin, uísque e outras bebidas destiladas.

- Componentes: Caldeira de destilação, coluna, cesto de gin, condensador.

- Destilação contínua com elevada eficiência e purificação do álcool.

- A coluna de cobre elimina os compostos de enxofre, melhorando o aroma e a pureza.

- Cesto de gin para uma produção flexível de gin.

5000L Cervejaria Sistema Turnkey Equipamento Exibição

Norma de produção do sistema chave na mão 5000L

- 5000L equipamento para cervejarias é adequado para fábricas de cerveja com uma estrutura inovadora e um aspeto bonito

- Todas as estruturas são feitas de aço inoxidável de qualidade alimentar SUS 304 e todos os tubos são feitos de SUS304

- Todos os depósitos são fornecidos com placas de dados, incluindo dados de ensaio e números de série

- Todos os tanques de armazenamento serão testados e inspeccionados na sala NDT para inspeção da construção e do controlo de qualidade

- Todos os casacos serão testados através de um ensaio de pressão de água, pressão de ensaio: 0,4Mpa (4 Bar) e pressão de funcionamento: 0,2Mpa (2Bar)

- Todos os depósitos de água são submetidos a um teste de pressão durante 48 horas antes de saírem da fábrica da MICET;

- Todas as soldaduras são soldadas com pinças de soldadura a laser para garantir uma forma uniforme e são submetidas a um tratamento de decapagem ácida e passivação.

- Todos os interiores dos reservatórios são polidos com espelho, Ra 0,4um.

Vantagens do sistema de fabrico de cerveja 5000L

Elevada capacidade e eficiência - 5KL por lote, 4-5 lotes diários, 9.000 toneladas por ano.

Automação e inteligência - PLC Siemens com automação total do processo, monitorização em tempo real e rastreio de dados.

Design multifuncional - Capaz de fabricar cerveja e produzir bebidas espirituosas, alargando a carteira de produtos.

Garantia de qualidade - O sistema avançado de arrefecimento e CIP garante uma fermentação estável, vitalidade da levedura e qualidade consistente da cerveja.

Modular e escalável - Conceção flexível do sistema, facilmente expansível para responder ao crescimento futuro da produção.

Se também estiver interessado no nosso equipamento de cervejaria, não hesite em contactar-nos Equipamento Meto. Em função das suas necessidades, recomendaremos o equipamento de cervejaria mais adequado e prestar-lhe-emos os serviços mais completos e de alta qualidade.