프로젝트 세부 정보:

위치: 중국

수제 맥주 시장이 빠르게 성장함에 따라 양조장에서는 더 큰 용량과 더 효율적인 양조 시스템에 대한 수요가 점점 더 커지고 있습니다. 이 프로젝트는 대용량과 효율성을 제공할 뿐만 아니라 자동화, 지능형 제어 및 다양한 생산을 위한 다기능 설계를 통합한 5000L 양조장 장비 설정을 특징으로 합니다.

이 양조장의 단일 배치 용량은 5KL로, 하루에 4~5개의 배치가 가능하며 연간 9,000톤을 생산할 수 있습니다. 이 시스템은 중대형 양조장 및 지역 맥주 시장의 수요를 충족하도록 설계되었습니다.

5000L 양조장 장비의 주요 구성

1. 밀링 시스템

- 맥아 리프팅 시스템, 건식 분쇄기, 유연한 이송 시스템을 갖춘 건식 밀링 기술.

- 용량: 시간당 3000kg의 맥아.

- 매시-물 혼합 시스템과 결합하여 수율과 추출 효율을 높입니다.

2. 양조장 시스템(5000L 4-용기)

- 구성: 매시 툰, 라우터 툰, 주전자, 월풀.

- 용량: 배치당 5KL, 하루 4~5배치.

- 공압식 폐곡물 시스템과 첨단 자동화를 갖추고 있습니다.

- 장점: 높은 효율성, 유연한 운영, 향후 확장을 위한 확장성.

3. 발효 시스템

- 구성: 5T, 10T, 20T 발효 탱크 및 밝은 맥주 탱크.

- 연간 용량: 약 9,000톤.

- 맥아즙, 맥주 공급, CIP, 압축 공기, CO₂ 및 배수를 위한 파이프라인이 있는 전면 발효 통로 레이아웃.

- 역할: 역할: 온도와 시간을 정밀하게 제어하여 맥주의 맛과 향, 바디의 안정성을 보장합니다.

4. 서비스 물 탱크

- 구성: 20T 글리콜 물 탱크, 20T 순수 물 탱크, 20T 온수 탱크, 펌프가 있는 20T 양조용 물 탱크.

- 기능: 일정한 온도와 압력으로 양조 및 CIP를 위한 안정적인 물 공급을 보장합니다.

5. 냉각 시스템

- 구성: 20T 글리콜 물 탱크, 30HP 냉각기 및 파이프 라인.

- 기능: 맥아즙 냉각, 발효 및 저온 저장을 위한 정확한 온도 제어로 효모 활력과 맥주 품질을 보장합니다.

6. CIP 클리닝 시스템

- 구성: 2T 가성 탱크, 2T 산성 탱크, 2T 살균제 탱크, 2T 온수 탱크, 펌프 및 파이프 라인.

- 기능: 완전 자동화된 세척 및 살균으로 위생적인 추출 조건을 보장합니다.

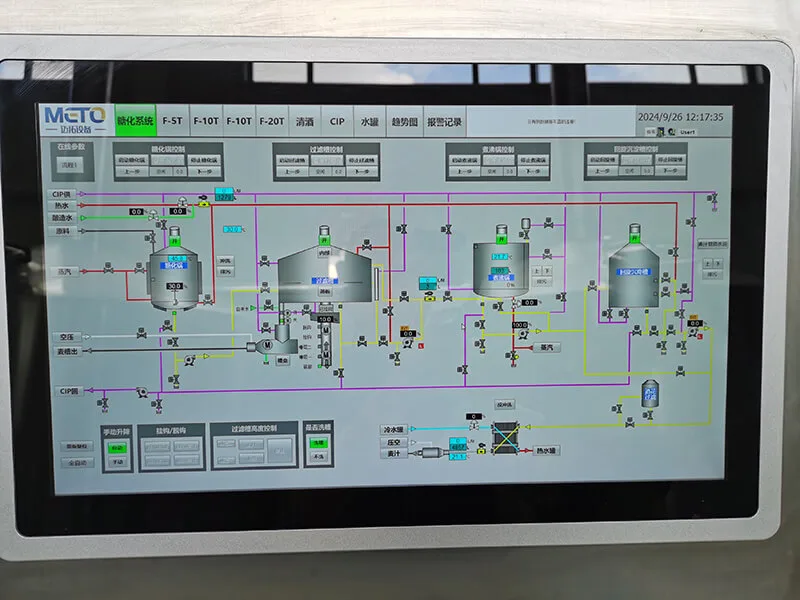

7. 제어 시스템

- 지멘스 1500 시리즈 PLC + WINCC SCADA 시스템.

- 양조장 및 발효 시스템을 위한 두 개의 독립적인 제어 스테이션.

- 기능: 전체 프로세스 자동화, 파라미터 추적, 실시간 모니터링, 일관된 맥주 품질.

8. 보조 파이프라인 시스템

- 맥아즙 파이프라인, 맥주 파이프라인, 랙 파이프라인, 효모 배출 파이프라인, CIP, 압축 공기 및 CO₂ 파이프라인이 포함됩니다.

9. 효모 분리 기계 및 플래시 저온 살균 시스템

- 용량: 시간당 5톤.

- PLC와 통합되어 정화부터 저온 살균까지 연속적인 무균 맥주 생산이 가능합니다.

10. 1000L 증류 장비

- 기술: 19세기 증기 추출 방식과 현대의 정밀 엔지니어링을 결합했습니다.

- 애플리케이션: 맥주 증류주, 진, 위스키 및 기타 증류주를 생산합니다.

- 구성품: 증류 주전자, 컬럼, 진 바스켓, 콘덴서.

- 고효율 및 알코올 정제를 통한 연속 증류.

- 구리 칼럼은 유황 화합물을 제거하여 향과 순도를 높입니다.

- 유연한 진 생산을 위한 진 바스켓.

5000L 양조장 턴키 시스템 장비 전시

5000L 턴키 시스템 생산 표준

- 5000L 양조장 장비 새로운 구조와 아름다운 외관을 가진 양조장에 적합합니다.

- 모든 구조물은 SUS 304 식품 등급 스테인리스 스틸로 만들어졌으며 모든 파이프는 SUS304로 제작되었습니다.

- 모든 탱크에는 테스트 데이터 및 일련 번호가 포함된 데이터 보드가 함께 제공됩니다.

- 모든 저장 탱크는 시공 및 품질 관리 검사를 위해 NDT 룸에서 테스트 및 검사됩니다.

- 모든 재킷은 수압 테스트, 테스트 압력: 0.4Mpa(4Bar) 및 작동 압력: 0.2Mpa(2Bar)를 사용하여 테스트됩니다.

- 모든 물탱크는 MICET 공장에서 출고되기 전에 48시간 동안 압력 테스트를 거칩니다;

- 모든 용접은 레이저 용접 클램프를 사용하여 균일한 모양을 보장하고 산세 및 부동태화 처리를 거칩니다.

- 모든 탱크 내부는 거울 광택, Ra 0.4um입니다.

5000L 추출 시스템의 장점

고용량 및 효율성 - 배치당 5KL, 매일 4~5배치, 연간 9,000톤.

자동화 및 인텔리전스 - 전체 프로세스 자동화, 실시간 모니터링 및 데이터 추적 기능을 갖춘 Siemens PLC.

다기능 디자인 - 맥주 양조 및 증류주 생산이 가능하여 제품 포트폴리오를 확장할 수 있습니다.

품질 보증 - 고급 냉각 및 CIP 시스템은 안정적인 발효, 효모 활력, 일관된 맥주 품질을 보장합니다.

모듈식 및 확장성 - 유연한 시스템 설계로 향후 생산량 증가에 맞춰 쉽게 확장할 수 있습니다.

양조장 장비에도 관심이 있으시면 언제든지 문의하십시오. 문의하기 메토 장비. 고객의 요구 사항에 따라 가장 적합한 양조장 장비를 추천하고 가장 포괄적이고 고품질의 서비스를 제공합니다.