Détail du projet :

Location:Chine

Avec la croissance rapide du marché de la bière artisanale, les brasseries ont de plus en plus besoin de systèmes de brassage de plus grande capacité et plus efficaces. Ce projet présente une installation de brassage de 5000 litres qui offre non seulement une capacité et une efficacité élevées, mais qui intègre également l'automatisation, un contrôle intelligent et une conception multifonctionnelle pour une production diversifiée.

La salle de brassage a une capacité de 5KL pour un seul lot, ce qui permet de produire 4 à 5 lots par jour et d'atteindre une production annuelle de 9 000 tonnes. Ce système est conçu pour répondre aux exigences des brasseries de taille moyenne à grande et des marchés régionaux de la bière.

Principale configuration de l'équipement de brasserie 5000L

1. Système de broyage

- Technologie de broyage à sec avec système de levage du malt, concasseur à sec et système de transport flexible.

- Capacité : 3000 kg de malt par heure.

- Combiné à un système de mélange eau-matière pour augmenter le rendement et l'efficacité du brassage.

2. Système de brassage (5000L 4 cuves)

- Composition : Cuve d'empâtage, cuve de clarification, bouilloire, bain à remous.

- Capacité : 5KL par lot, 4-5 lots par jour.

- Équipé d'un système pneumatique de traitement des drêches et d'une automatisation avancée.

- Avantages : Efficacité élevée, souplesse d'utilisation et évolutivité en vue d'une expansion future.

3. Système de fermentation

- Configuration : Cuves de fermentation 5T, 10T et 20T et cuves à bière claire.

- Capacité annuelle : environ 9 000 tonnes.

- Plan du couloir de fermentation avant avec les canalisations pour le moût, l'alimentation en bière, le NEP, l'air comprimé, le CO₂ et le drainage.

- Rôle : Contrôler avec précision la température et la durée, afin de garantir la stabilité des saveurs, des arômes et du corps de la bière.

4. Service Réservoirs d'eau

- Configuration : réservoir d'eau glycolée de 20 tonnes, réservoir d'eau pure de 20 tonnes, réservoir d'eau chaude de 20 tonnes, réservoir d'eau de brassage de 20 tonnes avec pompes.

- Fonction : Assure une alimentation stable en eau pour le brassage et le NEP avec une température et une pression constantes.

5. Système de refroidissement

- Configuration : réservoir d'eau glycolée de 20 tonnes, refroidisseur de 30 CV et canalisations.

- Fonction : Contrôle précis de la température pour le refroidissement du moût, la fermentation et le stockage au froid, garantissant la vitalité de la levure et la qualité de la bière.

6. Système de nettoyage CIP

- Configuration : réservoir de caustique de 2 tonnes, réservoir d'acide de 2 tonnes, réservoir d'assainisseur de 2 tonnes, réservoir d'eau chaude de 2 tonnes, pompes et canalisations.

- Fonction : Nettoyage et stérilisation entièrement automatisés, garantissant des conditions de brassage hygiéniques.

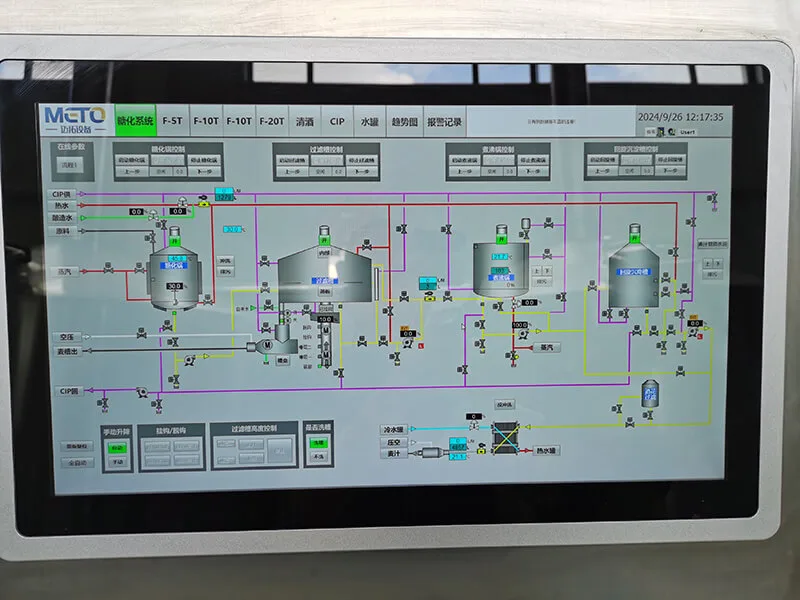

7. Système de contrôle

- PLC Siemens série 1500 + système SCADA WINCC.

- Deux postes de contrôle indépendants pour la salle de brassage et le système de fermentation.

- Fonction : Automatisation complète du processus, suivi des paramètres, contrôle en temps réel et qualité constante de la bière.

8. Système de canalisation auxiliaire

- Comprend le pipeline de moût, le pipeline de bière, le pipeline de soutirage, le pipeline d'évacuation de la levure, les pipelines de NEP, d'air comprimé et de CO₂.

9. Machine de séparation de la levure et système de pasteurisation flash

- Capacité : 5 tonnes/heure.

- Intégré à l'automate programmable pour une production continue et aseptique de bière, de la clarification à la pasteurisation.

10. Equipement de distillation 1000L

- Technologie : Combine l'extraction à la vapeur du 19e siècle avec une ingénierie de précision moderne.

- Applications : Production d'alcool de bière, de gin, de whisky et d'autres boissons distillées.

- Composants : Bouilloire de distillation, colonne, panier à gin, condenseur.

- Distillation continue à haut rendement et purification de l'alcool.

- La colonne de cuivre élimine les composés sulfurés, améliorant ainsi l'arôme et la pureté.

- Panier à gin pour une production flexible de gin.

5000L Système de brasserie clé en main Equipement Display

5000L système clé en main standard de production

- 5000L équipement de brasserie convient aux brasseries avec une structure originale et une belle apparence

- Toutes les structures sont en acier inoxydable SUS 304 de qualité alimentaire et tous les tuyaux sont en SUS304.

- Tous les réservoirs sont livrés avec des cartes de données comprenant les données de test et les numéros de série.

- Tous les réservoirs de stockage seront testés et inspectés dans la salle des essais non destructifs pour l'inspection de la construction et du contrôle de la qualité.

- Toutes les vestes seront testées à l'aide d'un essai de pression d'eau, pression d'essai : 0,4 Mpa (4 Bar) et pression de service : 0,2 Mpa (2 Bar).

- Tous les réservoirs d'eau sont testés sous pression pendant 48 heures avant de quitter l'usine MICET ;

- Toutes les soudures sont réalisées à l'aide de pinces à souder au laser afin de garantir une forme uniforme et sont soumises à un traitement de décapage à l'acide et de passivation.

- Tous les intérieurs de réservoirs sont polis miroir, Ra 0,4um.

Avantages du système de brassage 5000L

Capacité et efficacité élevées - 5KL par lot, 4-5 lots par jour, 9 000 tonnes par an.

Automatisation et intelligence - Automate Siemens avec automatisation complète des processus, surveillance en temps réel et suivi des données.

Conception multifonctionnelle - Capable de brasser de la bière et de produire des spiritueux, ce qui permet d'élargir le portefeuille de produits.

Assurance qualité - Le système de refroidissement et le système CIP avancés garantissent une fermentation stable, la vitalité de la levure et une qualité constante de la bière.

Modulaire et évolutif - Conception flexible du système, facilement extensible pour répondre à la croissance future de la production.

Si vous êtes également intéressé par notre équipement de brasserie, n'hésitez pas à nous contacter. nous contacter Meto Equipment. Nous vous recommanderons l'équipement de brasserie le mieux adapté à vos besoins et vous fournirons les services les plus complets et de la plus haute qualité.