Opening a craft beer bar or brewpub has become one of the most popular ways for entrepreneurs to enter the booming craft beer industry. Customers today appreciate fresh, high-quality beer with unique flavors, and installing an on-site microbrewery is the most effective way to create a distinctive brand identity.

To produce consistently great beer, choosing the right microbrewery equipment is essential. The equipment you invest in will directly determine beer quality, brewing efficiency, and your capacity for business growth.

This guide explains the key microbrewery equipment needed to open a craft beer bar, along with important planning and investment considerations.

Essential Microbrewery Equipment Needed for a Craft Beer Bar

1. Brewhouse System

The brewhouse system is the heart of any microbrewery. It includes several important vessels for converting grain into wort:

- Mash Tun – Mixes crushed malt and hot water to convert starch into sugar.

- Lauter Tun – Separates clear wort from spent grain.

- Brew Kettle – Boils wort and allows hop additions to build flavor, bitterness, and aroma.

- Whirlpool Tank – Removes solid particles and prepares wort for cooling.

Compact combination brewhouse designs are ideal for small-space craft beer bars and startup brewpubs.

2. Cooling System

Rapid cooling is critical for protecting beer flavor and preventing contamination:

- Plate Heat Exchanger – Quickly cools boiled wort to fermentation temperature.

- Glycol Chiller / Refrigeration System – Maintains precise temperature control during fermentation and storage.

A reliable cooling system affects beer stability and is one of the most important components in a microbrewery.

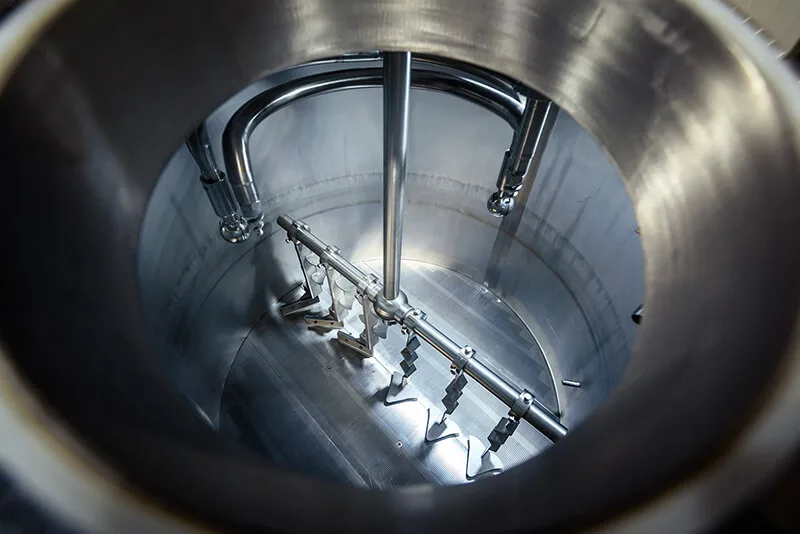

3. Fermentation and Conditioning Tanks

Once cooled, wort moves into fermentation tanks where yeast transforms it into beer:

- Fermentation Tank – Stainless steel tank with precise temperature control for primary fermentation.

- Bright Beer Tank – Used for carbonation, maturation, and clarification before serving.

Adding more fermentation tanks is the fastest and most cost-effective way to increase production capacity as your craft beer bar grows.

4. Beer Filtration, Kegging, and Packaging

Depending on your service model:

- Beer Filter – Improves clarity and stability by removing yeast and sediment.

- Keg Washer and Keg Filler – Essential for businesses serving draft beer.

- Bottling or Canning System – Optional for packaged products and takeaway sales.

Most new microbreweries start with keg dispensing and expand as demand increases.

Key Factors to Consider When Choosing Microbrewery Equipment

- Production Capacity – Estimate expected monthly output and number of taps. A 200L–500L system suits small bars, while 1,000L–2,000L is ideal for high-volume brewpubs.

- Space Planning – Consider equipment layout, storage, workflow, ventilation, and utilities.

- Scalability – Select equipment that supports expansion and modular upgrades.

- Material Quality – Choose food-grade stainless steel (304/316) for durability and hygiene.

结论

The success of a craft beer bar depends heavily on choosing the right microbrewery equipment. A well-designed brewing system ensures consistent beer quality, operational efficiency, and the ability to grow your brand over time. Whether starting with a compact microbrewery system or building a full-scale brewpub, smart equipment investment builds the foundation for long-term business success.

If you want to stand out in the competitive craft beer market, offering freshly brewed, unique beer made on site is one of the best strategies to attract loyal customers and increase profitability.

如果您对酿酒有任何疑问,请随时 联系我们 Meto 设备。