Beer Fermentation Tank Manufacturer

6-year warranty,competitive price with high quality

CE-PED/ASME/TUV/SGS/IS09001 certificatioh

Laser welding jacket, inner polishing,precision ≤0.4μm

OEM/0DM,Custom-built sizes from pilot 100L to 600HL+

One-stop turnkey brewery solutions available

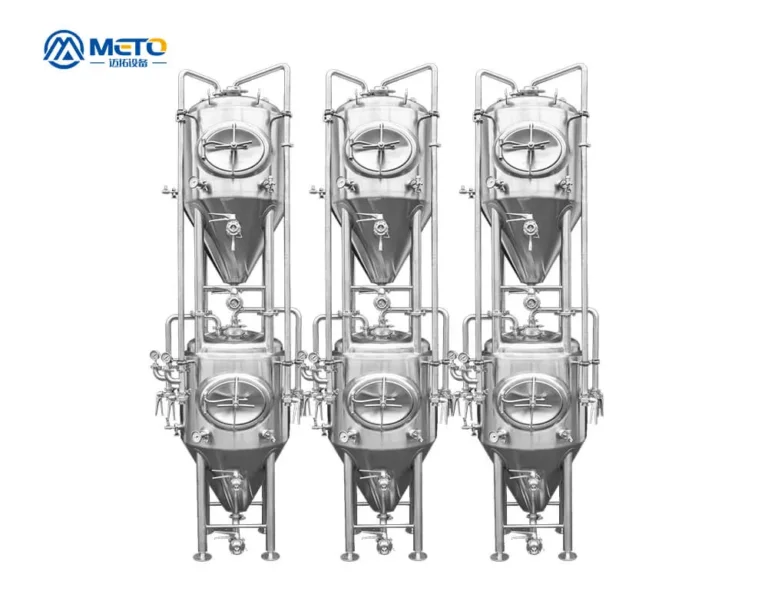

Beer Fermentation Tanks

We have 50L-200HL+ capacity for you to choose from. If you need help to select suitable beer fermenters for your projects, we are always here to support you. Meto is the most trusted place to purchase the beer fermenters for brewers and distributors.

Beer Fermentation Tank (100L – 200HL)

Standard Configuration of Beer Fermentation Tank

- Tank Capacity: custom (Min. Head Space: +25% )

- Interior Shell: Sus304 Full Welded; Th=3mm-4mm

- Exterior Shell:Sus304 Full Welded; Th=2mm

- 100% Tig Welding With Pure Argon Gas Shield

- Interior Finish: Sanitary 2B Finish, Passivated

- Exterior Finish: Wire Drawing Plate

- Interior Full Polished To 0.4 Μm Without Dead Corner

- Insulation: Th=80mm With Low Thermal Conductivity Pu

- Cooling Jacket: Dimple Plate On Bottom And Side Wall

- Dished Top Full Polished

- Conical Bottom With 60° Cone (Customizable)

- Top or Side Mounted Manhole With Pressured Door.

- Top Mounted 360° Rotary Cip Spraying Ball

- Cip Arm With Three-Way Connection And Butterfly Valve

- Mechanical Safe Valve Prv 2 Bar On Top (BBTS 3 Bar)

- Full Sanitary Sampling Valve/Pressure Gauge On Cip Arm

- Rotating Racking Arm And Port On Cone With Butterfly Valve (Fermenters)

- Discharge Arm With Butterfly Valve

- Thermowell For High Accuracy Temperature Sensor

- Dry Hopping Port 4” With Solid End Cap

Glycol Water In/Out Port On Cylinder / Glycol Water In/Out Port On Cone - Pressure Adjustable Bunging Valve

- 4 Pcs Completely Sus304 Legs With Braces

Your Solution for Flawless Fermentation

Make Your Brewery Project A Reality!

Whether you are an experienced brewer or new to the industry, Meto make it easy to bring your craft beer to life.

Unmatched Temperature Control

Full Glycol Jacketing & Insulation Achieve pinpoint accuracy throughout the entire brew, eliminating hot spots and ensuring perfect flavor development every time.

Pristine Yeast Management

All-in-One Efficiency (The Unitank)

Automated, Guaranteed Cleanliness

About us

Global High-end Fermentation Tank Provider

Meto was founded in 2013 with a strong focus on brewery equipment. "Brewing as your way, realizing your dream ". Meto preserve to become the trust worthy partner with craft beer practitioners.

Meto have been exported more than 95 countries and region as Europe, Asia, America ,Oceania and Affrica.

Equipment and services for more than 1,500 craft breweries

China’s top 10 craft brewing equipment companies.

More than 20 patented technologies, national high-tech enterprise, ISO 9001, CE Ped certified, SGS & TUV certified.

Frequently Questions

How long is the dilivery time?

- For standard models, our current delivery time is about 30 days

- Custom configurations may require additional time.

- Specific timelines will be provided with your formal quote.

Do you provide Installation & Debugging and Technical Service ?

- Installation & Debugging service:

METO technician will train the brewer to produce qualified craft beer.If the customer does not need our technician’s installation, we will also provide the installation diagrams, instructions to help them install by themselves.

- Technical Service:

METO will provide full Beer Brewing Equipment service including the whole brewing flow chart diagram, tanks assembling drawing, the floor plan blueprint, the electrical diagram, brewery space layout design in 3D plant and CAD drawing and also turnkey brewery service.

A

What is included in the standard warranty?

All our Professional Series tanks come with a comprehensive 6-year warranty that covers defects in materials and workmanship. We also offer optional extended warranty plans for added peace of mind.

Can the tanks be integrated with

METO provide installation and debugging service.

METO technician will train the brewer to produce qualified craft beer.

If the customer does not need our technician’s installation, we will also provide the installation diagrams, instructions to help them install by themselves.

Are accessories included with the tank?

Standard accessories include sample valve,pressure relief valve,thermometer,CIP spray ball and so on.Optional add-ons are also available.

Speak to an Expert

If you want to open your own dream brewery, please contact us. We have professional engineers and sales staff to answer all your questions.