Hot Sale Products

1000L Brewery Equipment

- High – efficiency brewhouse with Automatic Temperature Control for the brewing process

- High wort clarity and extraction rate thanks to optimized lauter tun and whirlpool design.

- 1000L equipment is suitable for Micro brewery.

- 304 food-grade stainless steel for all contact surfaces

- Pipe welding is weld outside and melt inside. Make acid passivation on inside.

- All tanks and glycol water jacket can bear 3bar pressure at most.

- All tank’s inner layer is 3mm thickness SUS 304 stainless steel. Outer layer is 2mm thickness SUS304 stainless steel.

- All raw material, spare parts and auxiliary machine are supplied buy famous supplier. We will inspect when they arrive at our factory, guarantee no problem.

Beer Brewery Equipment Manufacturer in China

As a leading manufacturer of beer machinery, I’m pleased to inform you that we have been working with many big companies in Europe and South America. We are in a good position not only to supply you high quality machinery, but also the excellent after sales service. Well-trained engineers will offer you any technical support.

Elevating Brewing Excellence – Tailored Equipment for Professionals

1000L Brewery Equipment Advantages

The 1000L brewery system is a perfect choice for small to medium-sized craft breweries. It combines efficiency, flexibility, and durability, making it ideal for both new startups and expanding operations.

- Optimal Brewing Capacity

With a 1000L brewhouse, breweries can balance production scale and investment. It provides sufficient output to meet market demand while allowing flexibility for recipe innovation and seasonal beers. - Consistent Quality & Efficiency

Equipped with advanced heating, lautering, and cooling technologies, the system ensures high wort yield, stable brewing cycles, and consistent beer quality batch after batch. - Flexible & Scalable Design

The system supports a wide variety of beer styles and can be easily expanded with additional fermenters and bright tanks as production grows. This makes it suitable for breweries with long-term development plans. - Premium Components & Durability

Constructed with food-grade stainless steel and fitted with internationally recognized pumps, valves, and control systems, the equipment guarantees long-lasting performance and reliability. - User-Friendly Operation

Available in semi-automatic or fully automated control modes, the system simplifies operation, reduces manual workload, and improves production accuracy. - Energy & Cost Efficiency

Designed with efficient heating and water recycling systems, the 1000L brewhouse lowers energy consumption and operating costs, supporting sustainable brewing practices. - International Standards Compliance

The equipment meets CE, UL, and other international certifications, ensuring safe, hygienic, and hassle-free installation in global markets.

1000L Brewery Equipment Configurations

For 1000L microbrewery equipment configurations, we focus on tailored solutions. We adjust every detail of the setup based on customers’ specific circumstances, including available site area, investment budget, and production targets, to provide equipment that perfectly matches their brewing operations and supports smooth production.

Malt Milling Unit

1. Function : Malt Crushing

2. ModelXW-G3

3. Ave. Capacity for Malt : 500kg/hour

4. Cover and Frame Material : Stainless steel

5. Drive Power : 1.5KW Motor CE ( UL Available )

6. Nylon and Chrome gear box for reducing running noise

7. Roller Diameter : 150mm,Total length of the roller :260mm,effective working length:110mm

Brewhouse Unit

Mash Lauter Tun〔1000L〕 1 Set

1. Function: Mashing & Lautering Process

2. Tank Capacity: 1000L (Min. Head Space: +40% )

3. Dimension: Φ1560x2500mm

4. Interior Shell: SUS304 full welded; TH=4mm

5. Exterior Shell:SUS304 full welded; TH=2mm

Kettle Whirlpool tank〔1000L〕 1 Set

1. Top dish head with full polished

2. 100% TIG welding with pure argon gas shield

3. Interior Finish: Sanitary 2B finish, Environmentally friendly cleaning and passivation; (8K Mirror finish optional)

4. Exterior Finish: Wire drawing plate

Hot Water Tank〔1500L〕 1 Set

1. Tank leakage test by water for 48 hours

2. Working Pressure : Atmosphere

3. Stainless Steel Manway Door

4. Heating way: Steam Heating

5. Heating Jacket on the bottom and cylinder

6. Installed steam safety valve , pressure gauge on cylinde

Fermentation Unit

1. Interior full polished to 0.4 μm without dead corner

2. Tank and Jacket Working Pressure: < 0.2Mpa

3. Leakage test by water and gas for 24 hours, tank test with 0.2Mpa, jacket test with 0.4Mpa

4. Dry hopping port 4” with solid end cap (Isotonic hops pitching tank for optional)

5. Conical bottom with 60° cone (customizable)

6. Sanitary top mounted oval manhole with pressured door (Side mounted is available)

Other Support Equipment

1. CIP chart

2. Glycol water tank

3. Chiller

4. Control carbinet

5. Bottle or cans filling machine

6. Keg filling and washing machine

7. Steam boiler

Projects Applications

Microbrewery

2 Vessels Brewhouse

Brewpubs or Restaurant Brewing Systems

3 Vessels Brewhouse

Beer R&D Laboratories

4 Vessels Brewhouse

Educational & Training Centers

Combined 3 Vessels Brewhouse

Brewing Experience Venues

3 Vessels Brewhouse

Small-scale Exhibitions or Temporary Production Sites

3 Vessels Brewhouse

1000L Brewery Equipment Parameters

| Model | MT-1000L |

| Capacity | 1000L/Batch |

| Brew/Day | 1-3 |

| Combination method | 2 vessels : Mash tun/Lauter tun, Kettle/whirlpool tank ; 3 vessels: Mash tun, Lauter tun,Kettle/whirlpool tank |

| Application | Restaurants, pubs, educational center, micro brewery |

| Heating way | Electric heating/Steam heating/Direct fire heating |

| Voltage | AC380/220V, 50/60HZ |

| Brewmaster | >1-2 |

| Height | >2.7m |

| Area Rquest | > 70m2 |

| Degree of automation | Manual / Semi-automatic / Fully automatic |

Looking For a Brewery Equipment Manufacturer?

Our Factory

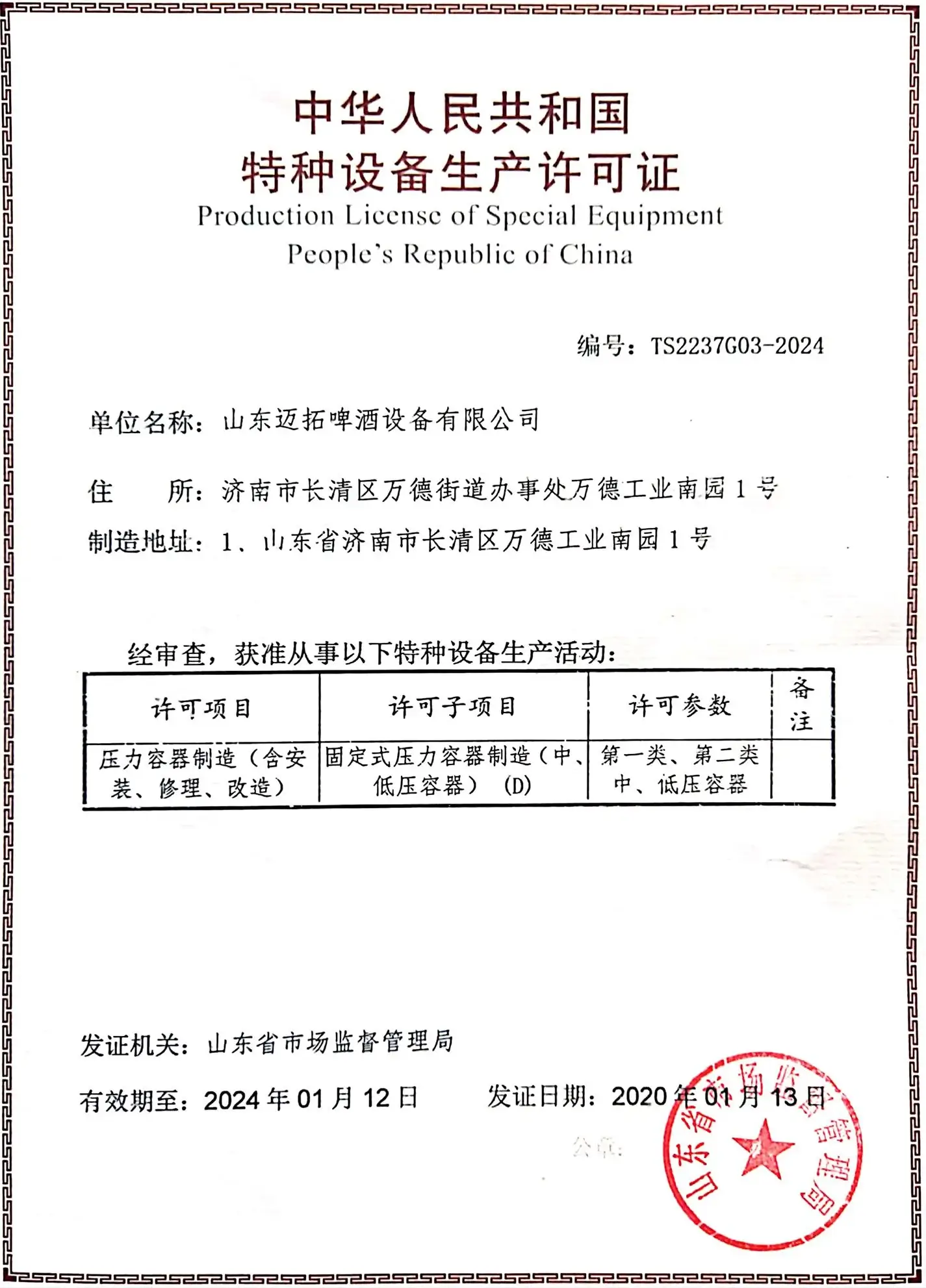

We are mainly engaged in turnkey project services such as beer equipment, distillation equipment, fruit wine equipment, rice wine equipment, etc. We’ve been serving clients in domestic and foreign trade since 2013. The company is located in Changqing District, Jinan, Shandong Province, with a factory area of 30,000 square meters and 120 employees. We focuses on the innovation and research and development of high-end, high-quality, and customized products. In terms of product quality assurance, our company’s products have passed ISO and CE certifications. Our product supports customer customization.

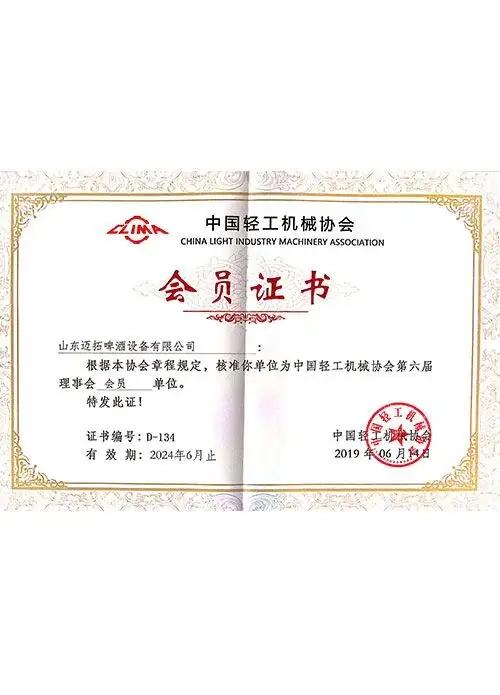

Our Certifications

Get Your Craft Brewing Solutions From METO !

Speak to an Expert

If you want to open your own dream brewery, please contact us. We have professional engineers and sales staff to answer all your questions.