In the evolving world of winemaking, stainless steel has become the material of choice for fermentation vessels. A stainless steel wine fermentation tank brings together durability, precision, and purity — meeting the demands of both modern wineries and discerning winemakers pursuing consistency and quality.

Purity of Flavor: Let the Grapes Speak

One of the most compelling reasons wineries choose stainless steel wine fermentation tanks is flavor neutrality. Unlike oak barrels, which impart woody, vanilla, or spice notes, stainless steel adds nothing but lets the natural fruit, acidity, and aromatic character of the grapes shine through. This neutrality is especially prized when the goal is a clean, crisp wine — such as a fresh white or a bright, fruit-forward red — where the true identity of the varietal should remain unmasked.

Moreover, because stainless steel is non-porous and inert, it avoids unwanted absorption or release of compounds into the wine. The result: wines that more faithfully reflect the grape, the vineyard, and the terroir.

Hygiene, Cleanliness and Ease of Maintenance

Sanitation is critical in winemaking — residue, microbes, or contaminants can spoil a batch. Stainless steel wine fermentation tanks offer a smooth, non-porous interior surface that resists bacterial growth, making cleaning and sterilization straightforward. Whether the tank is used repeatedly or left idle for long periods, it remains manageable to clean, sanitize, and maintain. This is far simpler and safer than older materials like wood or porous containers, which can hide residues or absorb unwanted flavors.

Additionally, many modern stainless steel tanks can be equipped with CIP (Clean-In-Place) systems or built-in cleaning mechanisms, allowing winemakers to rapidly sanitize between batches — saving time and reducing labor, especially important for larger-scale wineries.

Precise Temperature Control — Critical for Quality

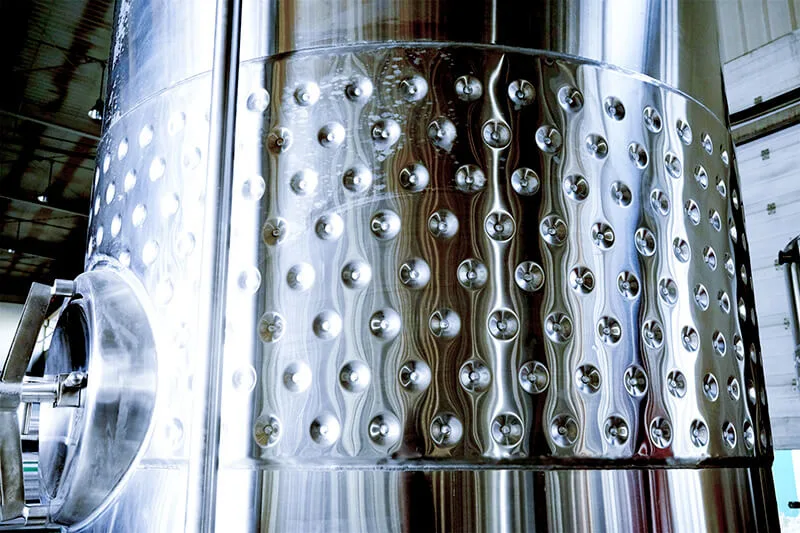

Fermentation is not a casual chemical reaction: managing temperature with precision is essential. Stainless steel wine fermentation tanks often come with integrated temperature-control features — cooling jackets, coils, or jackets that allow winemakers to regulate the must’s temperature throughout fermentation. This ability to maintain a consistent, optimal temperature helps promote healthy yeast activity, guard against stuck fermentation, and influence the extraction of flavors, tannins, acids — ultimately shaping the wine’s structure, aroma, and balance.

Whether producing delicate whites that benefit from cooler fermentation, or reds requiring warmer maceration, the fine control afforded by stainless steel tanks ensures repeatability and reliability — a key advantage for wineries that value consistency across vintages.

Long-Term Value: Durability, Cost Efficiency, and Scalability

While the initial investment in stainless steel wine fermentation tanks may be higher than simpler materials such as plastic or wood, their long-term value is significant. Stainless steel resists corrosion even under acidic conditions, remains structurally sound after years of use, and does not degrade or absorb flavors. As a result, these tanks can remain in service for decades with proper care and maintenance.

This longevity translates into cost savings over time: fewer replacements, less maintenance, and reduced risk of spoilage or contamination. For wineries scaling production — from small-batch craft wines to larger commercial output — stainless steel tanks offer flexibility: tanks of varying sizes and configurations can be utilized to match production needs without sacrificing quality or efficiency.

Versatility and Consistency: Meeting Diverse Winemaking Goals

Another advantage of stainless steel wine fermentation tanks is their adaptability. They suit a wide range of winemaking styles: from crisp whites to robust reds, from small boutique batches to large-scale production. Because they don’t impart additional flavors and because their properties remain consistent over time, they allow winemakers to produce wine that stays true to style — batch after batch — without unwanted variance.

Moreover, when the goal is to highlight the characteristics of the grape and vineyard — rather than add complexity from wood — stainless steel becomes the natural choice. For wineries focused on purity, clarity, and expressing terroir, stainless steel tanks let the wine speak for itself.

Conclusion: Stainless Steel Tanks as the Backbone of Modern Winemaking

The adoption of stainless steel wine fermentation tanks reflects an evolution in winemaking philosophy — one that emphasizes precision, consistency, hygiene, and fidelity to grape character. By offering neutral flavor impact, superior hygiene, precise temperature control, and long-term durability, these tanks give winemakers the tools to produce high-quality wines reliably and efficiently.

For both boutique artisanal wineries and larger commercial operations, stainless steel fermentation tanks represent a strategic investment: they help maintain the integrity of each vintage, reduce maintenance burdens, and allow scalability without compromising quality. In today’s competitive and quality-conscious wine industry, choosing stainless steel for fermentation is far more than a convenience — it’s a foundation for producing great wine.

Если у вас есть вопросы по пивоварению, пожалуйста, не стесняйтесь связаться с нами Оборудование Meto.