Produtos de venda a quente

Equipamento de fabrico de cerveja 500L | Sistema compacto de cerveja artesanal

- Aço inoxidável 304 durável, fácil de utilizar

- Garantia de 6 anos, preço competitivo com alta qualidade

- Sistemas compactos para microcervejarias, bares, restaurantes;Layout altamente flexível.

- Operação fácil (PLC ou sistema de controlo digital), reduz a dependência de fabricantes de cerveja profissionais

- até 95% eficiência de sacarificação , ±0,2°Pestabilidade do lote

- Prazo de execução: 30 dias (1 conjunto)

Fabricante de equipamento para cervejarias na China

O equipamento de cerveja artesanal da METO ganhou o reconhecimento de inúmeros clientes no país e no estrangeiro pela sua qualidade fiável, desempenho superior e excelente serviço. Podemos fornecer-lhe equipamento artesanal altamente qualificado.

Fornecedor mundial de equipamento para cervejeiras de topo de gama

Vantagem do equipamento de cervejaria 500L

O sistema de equipamento de cerveja artesanal 500L permite aos pequenos e médios empresários entrar no mercado da cerveja artesanal com um investimento relativamente baixo, um funcionamento flexível e a capacidade de produzir uma vasta gama de cervejas únicas.

Escala comercial ideal e flexibilidade

Esta saída é perfeitamente adequada para pequenas cervejarias artesanais, brewpubs ou grandes bares. Fornece volume suficiente para vendas comerciais, permitindo ao fabricante de cerveja a flexibilidade de produzir diferentes estilos de cerveja (por exemplo, IPA, Stout, Cerveja de Trigo) em lotes separados, evitando o risco de excesso de stock de um único lote grande.

Conceção modular

Os tanques, tubagens e plataformas são concebidos como uma combinação modular com ligações de encaixe rápido para uma rápida

instalação. Design humanizado, operação mais simples. Manutenção conveniente, reduz os custos de manutenção. Fornece uma interface expansível para satisfazer as necessidades de atualização do equipamento.

Fácil de utilizar e de controlar

Para cervejeiros caseiros experientes em transição para cervejeiros profissionais, processos como troca de calor, bombagem e controlo de temperatura num sistema de 500L são mais intuitivos e reactivos do que em configurações maiores. Isto permite um melhor controlo do processo de fabrico de cerveja, garantindo a qualidade de cada lote.

Funcionalidade abrangente e processo completo

Um sistema padrão de 500L integra tipicamente uma tina de brassagem, uma tina de lauterização, uma caldeira de ebulição e um redemoinho, incluindo frequentemente um sistema CIP (Cleaning-In-Place) automatizado. Isto significa que todos os processos-chave, desde a moagem até à pré-fermentação, podem ser concluídos num único sistema sem etapas de transferência adicionais.

Garante a qualidade e a consistência

Os sistemas modernos de 500L estão frequentemente equipados com sistemas de controlo automatizados precisos (por exemplo, PLC) para gerir com exatidão as temperaturas de brassagem e de ebulição. Esta precisão repetível é fundamental para garantir um sabor de cerveja estável e uma consistência de lote para lote, o que ajuda a construir uma reputação de marca fiável.

Configurações do equipamento da cervejaria de 500L

O equipamento para microcervejarias da Meto é a escolha ideal para cervejarias, taprooms, restaurantes, bares, hotéis e cervejarias de pequena escala. Apresenta um processamento rápido, facilidade de operação, qualidade de topo e uma longa vida útil. O investimento pode ser totalmente recuperado num prazo de 1 a 2 anos.

Unidade de moagem de malte

Ave. Capacidade para malte: 200-300kg/hora

A tremonha standard tem capacidade para 12 kg de malte

Material da tampa e da estrutura: aço inoxidável

- Triturador de rolo duplo 1000kgs/h

- Sem-fim flexível ou flexível para elevar diretamente o grão moído para a cuba de trituração

- Tremonha de grãos com hidratador

Unidade de fabrico de cerveja

- 2/3/4/5 recipientes, Combinado 3 recipientes Triturar Lauter Kettle Whirlpool Process

Unidade de fermentação

- Capacidade do depósito: 500L (espaço mínimo para a cabeça: +25% )

- Concha exterior: SUS304 totalmente soldado; TH=2mm

- Isolamento: TH=80mm com PU de baixa condutividade térmica

- Interior totalmente polido até 0,4 μm sem cantos mortos

- Pressão de trabalho do tanque e da camisa: < 0.2Mpa

Unidade de arrefecimento de glicol

- Tanque de água glicolada

- Refrigerador de água de glicol

- Transferência de água de glicol (bomba e tubagem)

Unidade CIP

- Bomba móvel CIP

- Carrinho CIP

- Estação CIP

Unidade de controlo de potência

- Armário de controlo PID

- Armário de controlo PLC para opção

- Semi-automático ou totalmente automático para a sala de brassagem e o processo de fermentação

Projectos Aplicações

Microcervejaria

Cervejaria de 2 recipientes

Sistemas de fabrico de cerveja para cervejarias ou restaurantes

Cervejaria 3 Vasos

Laboratórios de I&D de cerveja

Cervejaria 3 Vasos

Centros de ensino e formação

Cervejaria combinada de 3 recipientes

Locais de experiência cervejeira

Cervejaria de 2 recipientes

Exposições de pequena escala ou locais de produção temporária

Cervejaria de 2 recipientes

Parâmetros do equipamento da cervejaria 500L

| Modelo | MT-500L |

| Capacidade | 500L/lote |

| Cerveja/Dia | 1-2 |

| Método de combinação | Tina de brassagem, tina de Lauter, chaleira/tanque de hidromassagem |

| Aplicação | Restaurantes, bares, hotéis, cervejaria |

| Modo de aquecimento | Aquecimento elétrico/Aquecimento a vapor/Aquecimento por fogo direto |

| Tensão | 220V/380V ou personalizado |

| Mestre cervejeiro | 1 |

| altura | >2.5m |

| Área Rquest | >45M² |

| Grau de automatização | Manual / Semi-atuo / Totalmente automático |

Procura um fabricante de equipamento para cervejarias?

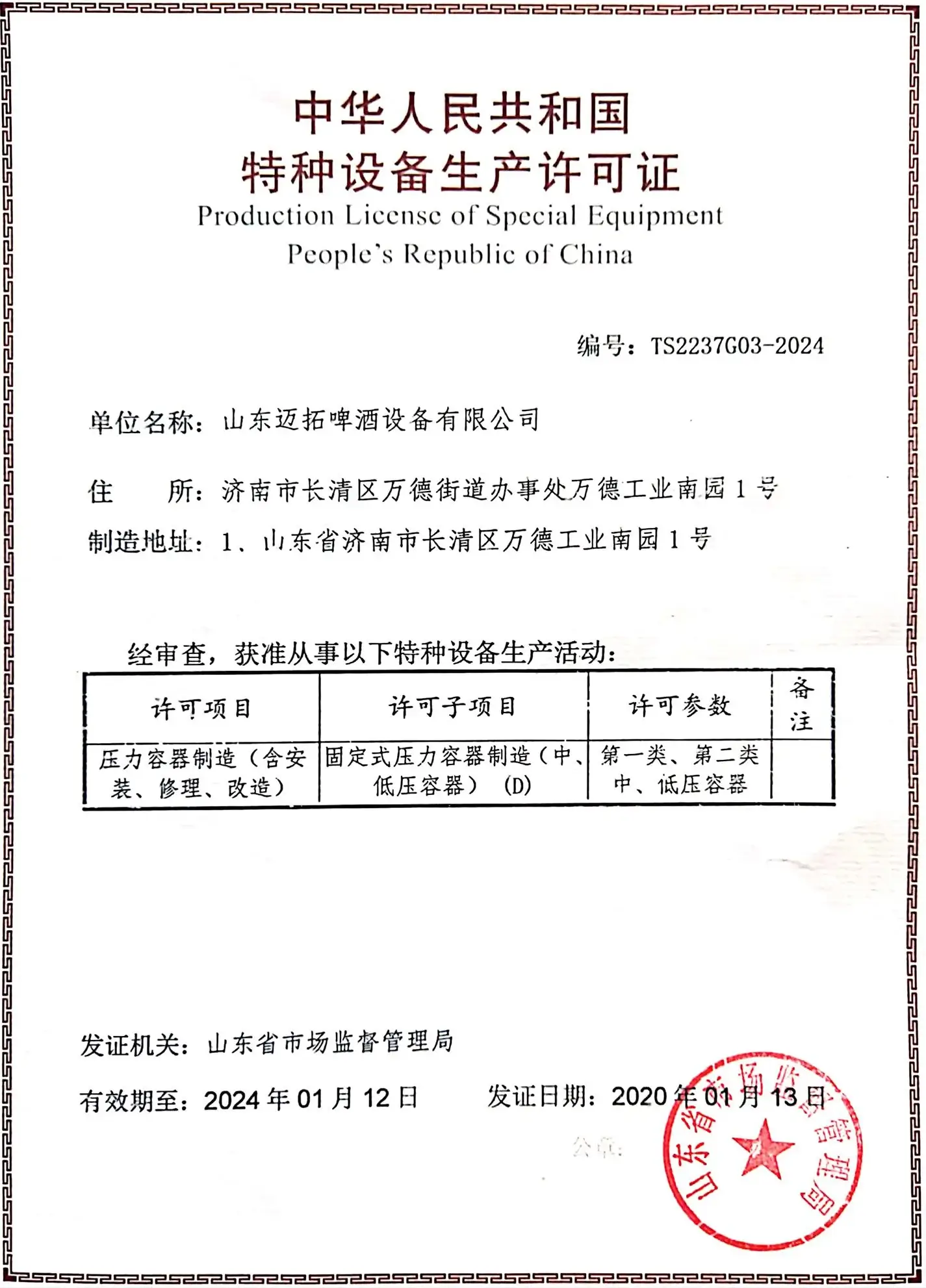

As nossas certificações

Obtenha as suas soluções de fabrico de cerveja artesanal na METO!

Falar com um especialista

Se quiser abrir a sua própria fábrica de cerveja de sonho, contacte-nos. Temos engenheiros profissionais e pessoal de vendas para responder a todas as suas perguntas.