For beer producers, improving fermentation efficiency is critical for increasing output, shortening production cycles, and maintaining stable beer quality.

In a 5-ton brewhouse system, fermentation efficiency depends not only on yeast performance, but also on mash conversion, process control, equipment matching, and automation level.

Below is a practical guide to improving fermentation efficiency in a 5-ton craft beer brewing system, covering five key areas: mash optimization, yeast management, fermentation environment control, equipment configuration, and advanced technology.

1. Mash Process Optimization: Increase Fermentable Sugar Yield

Fermentation speed is directly related to how quickly yeast can consume fermentable sugars.

During mashing, the goal is to maximize fermentable sugars (such as maltose and glucose) while minimizing non-fermentable dextrins.

Step Mashing Temperature Control

Protein Rest (52–55°C, 20 minutes)

Breaks down large proteins into amino acids, providing nutrients for yeast and improving fermentation activity.

β-Amylase Rest (62–65°C, 30–40 minutes)

Converts starch into short-chain fermentable sugars, mainly maltose.

α-Amylase Rest (68–70°C, 10 minutes)

Further breaks down long-chain dextrins to prevent slow or incomplete fermentation.

Iodine Test

After mashing, add iodine to a wort sample. No blue color indicates complete starch conversion.

Lautering and Sparging Optimization

- Lautering time: Keep within 90 minutes to avoid grain bed compaction and sugar loss

- Sparge water ratio: 1:1.5 (grain to water) at 75°C

- Original gravity (OG): Target 12–14°P

- Too high → longer fermentation

- Too low → reduced alcohol yield

Enzyme Addition (Optional)

Adding commercial enzymes before fermentation can further convert dextrins into fermentable sugars, increasing attenuation and fermentation speed.

2. Yeast Management: Improve Yeast Activity and Stability

Yeast performance is the direct driver of fermentation efficiency. Proper strain selection, activation, and pitching rate are essential.

Yeast Selection

- Ale yeasts: US-05, S-04 (attenuation 75–85%)

- Lager yeasts: W-34/70 for clean and stable fermentation

- Pressure-tolerant yeast: Recommended if fermentation pressure reaches 0.15–0.2 MPa

Yeast Activation and Pitching

- Dry yeast rehydration:

1:10 yeast-to-water ratio at 35°C

Add 10% wort or yeast nutrient, rest for 30 minutes - Pitching rate (5-ton wort):

- Dry yeast: 200–300 g

- Liquid yeast: 2–3 L

- Target cell count: ≥1×10⁷ CFU/mL

- Viability standard:

- Budding rate ≥60%

- Dead cells ≤5%

Wort Oxygenation

- Dissolved oxygen at pitching: ≥8 mg/L

- Use pure oxygen or Venturi system

- Avoid excessive agitation during mid and late fermentation to prevent yeast damage

3. Fermentation Environment Control: Temperature, Pressure, and pH

Fermentation conditions strongly affect yeast metabolism and flavor development.

Temperature Control Strategy

Main fermentation (3–5 days)

Gradually reduce temperature by 1–2°C per day

- Ale: down to 5–8°C

- Lager: down to 0–2°C

This helps complete sugar consumption while preventing yeast autolysis.

Maturation phase (5–7 days)

Maintain stable low temperature to improve flavor stability and clarity.

Pressure Control

- Open or low-pressure fermentation in early stages helps CO₂ release

- Apply pressure (0.1–0.15 MPa) in later stages to improve yeast settling and flavor consistency

PH Control

Maintain fermentation pH between 4.2 and 4.6

This range supports enzyme activity, yeast health, and microbial stability.

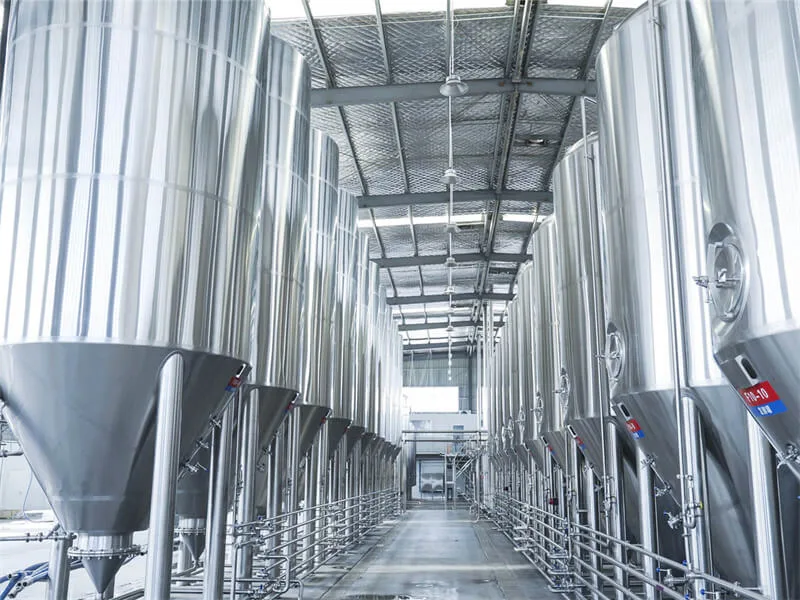

4. Equipment Matching: Avoid Process Bottlenecks

A 5-ton brewhouse system must be properly matched with fermentation and cooling capacity.

Brewhouse and Fermenter Matching

- Brewhouse output slightly higher than fermenter volume

(e.g. 6 tons wort into a 5-ton fermenter) - Leave headspace to prevent over-foaming

- Fermenter height-to-diameter ratio: 1:2 to 1:3

Wort Cooling System

- Plate heat exchanger:

Cool wort to pitching temperature within 30 minutes- Ale: ~20°C

- Lager: ~10°C

- Glycol cooling system:

Dedicated glycol tank with PID temperature control ensures stable cooling rates

Automation and Monitoring

- Sensors for temperature, pressure, dissolved oxygen, and gravity

- Automatic temperature programs reduce manual error and labor cost

5. Advanced Technologies: Improve Efficiency with Smart Brewing

Intelligent Brewhouse Systems

- IoT-based temperature and pH monitoring

- One-click mash programs

- Reduce mash time by up to 20%

High-Efficiency Wort Clarification

- Vortex or centrifugal filtration

- Reduce lautering time by 50%

- Improve wort clarity to over 95%

Low-Pressure Boiling and Heat Recovery

- Boiling at 92–95°C reduces aroma loss

- Heat recovery systems can reduce energy consumption by up to 30%

Yeast Monitoring and AI Optimization

- Optical sensors track yeast activity in real time

- Automatic adjustment of temperature and oxygen supply

- Fermentation time reduced by up to 15%

- AI-based maintenance alerts help prevent contamination and equipment failure

Industry Outlook

With new craft beer standards and regulations expected to align with European and American markets, small and medium craft breweries will gain greater access to packaged beer sales.

This creates a strong opportunity for breweries equipped with efficient, stable, and intelligent brewing systems.

If you have any questions about brewing technology or equipment solutions, feel free to contattare Meto.