Produits en vente directe

Équipement de brassage 500L | Système compact de bière artisanale

- Acier inoxydable 304 durable, facile à utiliser

- Garantie de 6 ans, prix compétitif et haute qualité

- Systèmes compacts pour les microbrasseries, les bars et les restaurants.

- Fonctionnement facile (système de contrôle PLC ou numérique), réduisant la dépendance à l'égard des brasseurs professionnels.

- jusqu'à 95% efficacité de la saccharification, ±0,2°P stabilité du lot

- Délai de livraison : 30 jours (1 set)

Fabricant d'équipements de brasserie en Chine

Le matériel de fabrication de bière artisanale de METO a gagné la reconnaissance de nombreux clients dans le pays et à l'étranger grâce à sa qualité fiable, ses performances supérieures et son excellent service. Nous pouvons vous fournir des équipements artisanaux de haute qualité.

Fournisseur mondial d'équipements de brasserie haut de gamme

Equipement de brasserie 500L Advantage

Le système d'équipement de bière artisanale 500L permet aux petites et moyennes entreprises d'entrer sur le marché de la bière artisanale avec un investissement relativement faible, un fonctionnement flexible et la capacité de produire une large gamme de bières uniques.

Une échelle commerciale et une flexibilité idéales

Cette sortie convient parfaitement aux petites brasseries artisanales, aux brasseries et aux grands bars. Il fournit un volume suffisant pour les ventes commerciales tout en permettant au brasseur de produire différents styles de bière (par exemple, IPA, Stout, Wheat Beer) dans des lots séparés, évitant ainsi le risque de surstockage d'un seul lot important.

Conception modulaire

Les réservoirs, les pipelines et les plates-formes sont conçus comme une combinaison modulaire avec des raccords rapides pour une mise en œuvre rapide.

l'installation. Conception humanisée, fonctionnement plus simple. Maintenance pratique, réduction des coûts de maintenance. Interface extensible pour répondre aux besoins de mise à niveau de l'équipement.

Convivialité et facilité de contrôle

Pour les brasseurs amateurs expérimentés qui deviennent des brasseurs professionnels, les processus tels que l'échange de chaleur, le pompage et le contrôle de la température dans un système de 500 litres sont plus intuitifs et plus réactifs que dans les installations plus grandes. Cela permet de contrôler plus finement le processus de brassage et d'assurer la qualité de chaque lot.

Fonctionnalité complète et processus complet

Un système standard de 500 litres intègre généralement une cuve d'empâtage, une cuve de clarification, une bouilloire et un bain à remous, et comprend souvent un système automatisé de nettoyage en place (NEP). Cela signifie que tous les processus clés, de la mouture à la pré-fermentation, peuvent être réalisés dans un seul système, sans étapes de transfert supplémentaires.

Garantir la qualité et la cohérence

Les systèmes 500L modernes sont souvent équipés de systèmes de contrôle automatisés précis (par exemple, PLC) pour gérer avec exactitude les températures d'empâtage et d'ébullition. Cette précision reproductible est essentielle pour garantir la stabilité de la saveur de la bière et l'homogénéité d'un lot à l'autre, ce qui contribue à asseoir la réputation d'une marque fiable.

Configurations de l'équipement de la brasserie 500L

L'équipement de microbrasserie Meto est un choix idéal pour les brasseries, les salles de dégustation, les restaurants, les bars, les hôtels et les brasseries à petite échelle. Il se caractérise par un traitement rapide, une facilité d'utilisation, une qualité supérieure et une longue durée de vie. L'investissement peut être entièrement amorti en 1 à 2 ans.

Unité de broyage du malt

Capacité de malt : 200-300kg/heure Capacité pour le malt : 200-300kg/heure

La trémie standard peut contenir 12 kg de malt

Matériau du couvercle et du cadre : acier inoxydable

- Concasseur à double rouleau 1000kgs/h

- Vis sans fin souple ou flexible pour soulever directement le grain broyé jusqu'à la cuve d'empâtage

- Trémie à grains avec hydrateur

Unité de brassage

- 2/3/4/5 cuves, combiné 3 cuves Mash Lauter Kettle Whirlpool Process

Unité de fermentation

- Capacité du réservoir : 500L (hauteur de chute minimale : +25%)

- Coque extérieure : SUS304 entièrement soudé ; TH=2mm

- Isolation : TH=80mm avec du PU à faible conductivité thermique

- Intérieur entièrement poli à 0,4 μm sans angle mort.

- Pression de travail du réservoir et de l'enveloppe : < 0.2Mpa

Unité de refroidissement au glycol

- Réservoir d'eau glycolée

- Refroidisseur d'eau au glycol

- Transfert d'eau glycolée (pompe et tuyauterie)

Unité CIP

- Pompe mobile CIP

- Panier CIP

- Station CIP

Unité de contrôle de la puissance

- Armoire de contrôle PID

- Armoire de contrôle PLC en option

- Semi-automatique ou entièrement automatique pour la salle de brassage et le processus de fermentation

Projets Applications

Microbrasserie

Brasserie 2 Vaisseaux

Systèmes de brassage pour brasseries ou restaurants

Brasserie des 3 vaisseaux

Laboratoires de R&D pour la bière

Brasserie des 3 vaisseaux

Centres d'éducation et de formation

Salle de brassage combinée à 3 cuves

Sites de l'expérience brassicole

Brasserie 2 Vaisseaux

Expositions à petite échelle ou sites de production temporaires

Brasserie 2 Vaisseaux

Paramètres de l'équipement de brasserie 500L

| Modèle | MT-500L |

| Capacité | 500L/Lot |

| Brassage/jour | 1-2 |

| Méthode de combinaison | Cuve d'empâtage, cuve de clarification, bouilloire/cuve d'hydromassage |

| Application | Restaurants, bars, hôtels, brasseries |

| Mode de chauffage | Chauffage électrique/Chauffage à vapeur/Chauffage à feu direct |

| Tension | 220V/380V ou personnalisé |

| Maître-brasseur | 1 |

| hauteur | >2.5m |

| Demande de zone | >45M² |

| Degré d'automatisation | Manuel / Semi-automatique / Automatique |

Vous cherchez un fabricant d'équipement de brasserie ?

Notre usine

Chez Meto, nous combinons des équipements de pointe et une innovation permanente pour fournir des équipements de brasserie et des services à notre clientèle mondiale. Découvrez les avantages d'un partenariat avec une usine engagée dans la technologie, l'innovation et la satisfaction du client.

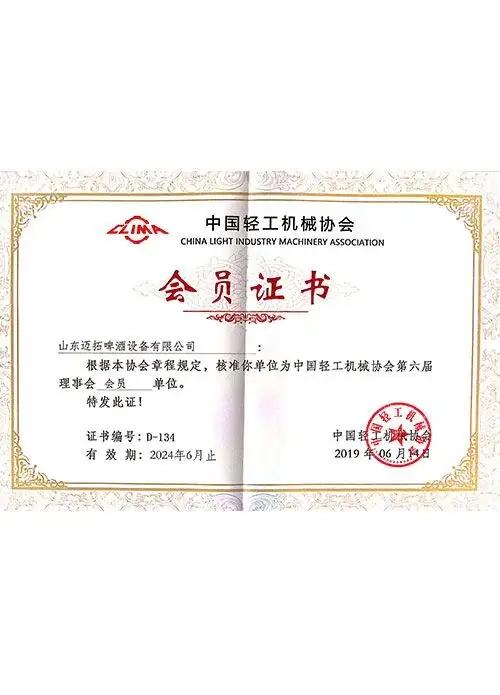

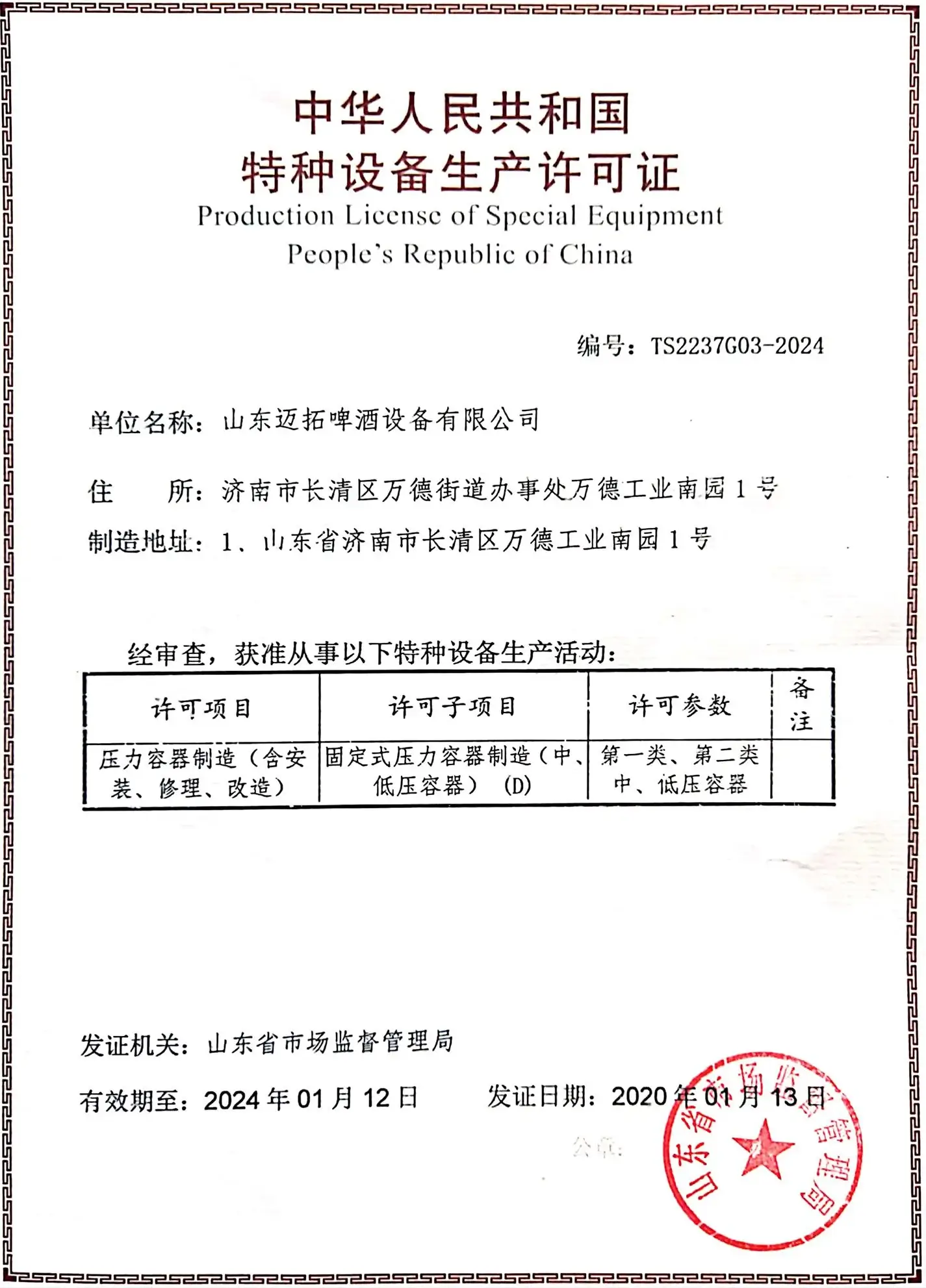

Nos certifications

Obtenez vos solutions de brassage artisanal auprès de METO !

Parler à un expert

Si vous souhaitez ouvrir la brasserie de vos rêves, n'hésitez pas à nous contacter. Nous disposons d'ingénieurs et de vendeurs professionnels pour répondre à toutes vos questions.