Productos más vendidos

200L Brewery Equipment

- 304 food-grade stainless steel for all contact surfaces.

- 6 años de garantía, precio competitivo y alta calidad

- All tanks and glycol water jacket can bear 3bar pressure at most.

- Easy operation(PLC or Digital control system), reduces reliance on professional brewers

- High – efficiency brewhouse with Automatic Temperature Control for the brewing process

Leading Brewery Equipment Manufacturer In China

El equipo de cerveza artesanal METO ha ganado el reconocimiento de numerosos clientes en el país y en el extranjero por su calidad fiable, rendimiento superior y excelente servicio. Podemos suministrar equipos artesanales altamente cualificados para usted.

Meto continuously integrates advanced process design philosophies, production management experience, and quality inspection standards from Europe and America. Emphasizing innovation and creativity, the company focuses on the development of high-end, precision, and customized products. Through years of dedication, Meto has developed the capability to combine “Chinese Manufacturing with European and American Standards.” Its rigorous professionalism and customer-oriented services have earned widespread recognition and trust within the industry.

Quality Control

Custom Design

Fast Delivery

Asistencia posventa

Excellent Reputation

200L Brewery Equipment Advantages

The 200L craft beer system is an ideal choice for flexible, small-scale entrepreneurship, perfectly aligning with the craft beer ethos of being “small-batch, quality-driven, and innovative.”

Compact Size, Flexible Layout

Featuring a compact or modular design, the system requires only about 15-25㎡ of space for installation, easily adapting to various venues like urban storefronts or basements.

Low Investment, Quick ROI

The initial cost is significantly lower than large industrial systems, making it ideal for individual entrepreneurs, small bars, or restaurants. The high value-added nature of craft beer can lead to a relatively short payback period with proper operation.

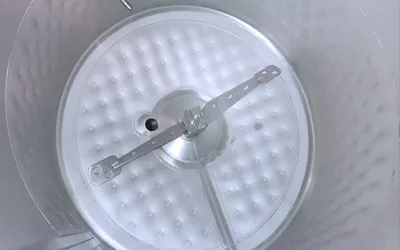

Efficient & Easy Cleaning

With good thermal and mashing efficiency, along with often integrated CIP (Clean-in-Place) systems, it saves utilities, reduces labor, and ensures strict hygiene and food safety standards.

User-Friendly Operation, Consistent Quality

Often equipped with semi or fully automated control systems (e.g., PLC), it ensures precise temperature control during mashing and fermentation, reducing reliance on brewing expertise and guaranteeing consistent beer flavor.

Production Flexibility, Diverse Styles

Capable of brewing both Ales and Lagers, it easily supports special processes like dry-hopping and fruit infusion, enabling innovation and meeting diverse market demands.

200L Brewery Equipment Configurations

For 200L microbrewery equipment configurations, we focus on tailored solutions. We adjust every detail of the setup based on customers’ specific circumstances, including available site area, investment budget, and production targets, to provide equipment that perfectly matches their brewing operations and supports smooth production.

Sistemas principales

1.Unidad de molienda de malta

- 2 Vessels: Mash/Lauter + Kettle/Whirlpool + Hot Water Tank

- Ave. Capacity for Malt : 50-100kg/hour

- Cover and Frame Material : Stainless stee

- Roller Material : Hardening chrome steel , washable

- Ddimension : 900mm*500mm*280mm

- Standard hopper can hold 12kg malt.

2. Unidad de cocción

- 2 Vessels: Mash/Lauter + Kettle/Whirlpool + Hot Water Tank

Combined 3 Vessels: Lauter(Up) & Whirlpool(Down) + Mash/Kettle

Combined 3 Vessels: Mash/Lauter(Up) & Holding tank(Down) + Kettle/Whirlpool

3 Vessels: Mash + Lauter + Kettle/Whirlpool - Useful capacity: 200L/ batch (30% headspace)

- Dimensions: 3100mm x 860mm x 1500mm

- Interior Shell: SUS304 full welded; TH=3mm

- Exterior Shell:SUS304 full welded; TH=2mm

- Stainless steel control cabinet

3.Fermentation Unit

- Depósito de agua glicolada

- Enfriadora de agua glicolada

- Trasvase de agua glicolada ( Bomba y tubería )

4.Unidad de refrigeración por glicol

- Glycol Water Tank〔500L〕

- Glycol Water Chiller〔2P〕

- Trasvase de agua glicolada ( Bomba y tubería )

5.Unidad CIP

- CIP Portable Pump

- Carro CIP

- Estación CIP

6.Unidad de control de potencia

- Armario de control PID

- Armario de control PLC opcional

- Semiautomático o totalmente automático para la sala de cocción y el proceso de fermentación

200L Brewery Equipment Parameters

| Modelo | MT-200L |

| Capacidad | 200L/Batch |

| Cerveza/Día | 1-2 |

| Método combinado | 2 vessels/ combined 3 vessels/ 3 vessels |

| Aplicación | Restaurantes, pubs, centro educativo, microcervecería |

| Calefacción | Calefacción eléctrica/Calefacción por vapor/Calefacción por fuego directo |

| Tensión | AC380/220V,50/60HZ |

| Maestro cervecero | >1 |

| Altura | >2.1m |

| Área Rquest | 18-25m2 |

| Grado de automatización | Manual / Semiautomático / Automático |

FAQ of 200L Brewery Equipment

What beer styles can it produce?

- Ales, Lagers, Stouts, Wheat beers, and fruit-infused variants

- Open fermentation options for traditional Czech-style lagers

- How many operators are needed?

What materials are used, and are they sanitary?

All SUS304 or 316L stainless steel

What after-sales support is provided?

- Warranty: 6 years for core components

- Services: Installation, training, and technical support offered by most suppliers

¿Cuál es el plazo de entrega?

- For standard models, our current delivery time is about 30 days

- Las configuraciones personalizadas pueden requerir más tiempo.

- El presupuesto formal irá acompañado de plazos concretos.

Can the system be upgraded or expanded in the future?

Yes, modularity is key. we design systems with expansion in mind.

Common Upgrades: Adding more fermentation tanks is the easiest way to increase total output. You can also upgrade control systems from manual to semi-automatic or fully automatic PLC.If you want more information,feel free to contanct us.

What is the difference between 2-vessel and 3-vessel brewhouse designs for a 200L system?

2-Vessel System :More compact and cost-effective. One vessel acts as a combined Mash/Lauter Tun, and the other is a combined Kettle/Hot Liquor Tank.

3-Vessel System (MT, LT, KT): Allows for concurrent processes. You can mash one batch while boiling another, significantly increasing daily output.

Looking For a Nano Brewery Equipment ?

About METO

Founded in 2013, Meto is an international fermentation equipment manufacturer specializing in turnkey project services for beer brewing, distillation, fruit wine, and rice wine systems. With 70% of its products exported to over 100 countries and regions, the company has served more than 3,000 clients globally, including over 1,000 domestic clients in China. Meto equipment is increasingly becoming essential for craft brewers worldwide.

The company is located in Changqing District, Jinan, Shandong Province, with a factory area of 30,000 square meters and 120 employees.

Trustworthy quality

The technical R&D and production management team at Meto boasts an average of over 15 years of industry experience. The company has obtained more than 20 technological innovation patents and has been recognized as a National High-Tech Enterprise. It also holds various certifications including Pressure Vessel Manufacturing License, EU CE Certification, ISO 9001 Quality Management System Certification, and ISO 18001 Occupational Health and Safety Management System Certification.

What our clients say?

Request an Instant Quote for Your Project!

Si desea abrir la fábrica de cerveza de sus sueños, póngase en contacto con nosotros. Contamos con ingenieros profesionales y personal de ventas para responder a todas sus preguntas.