Als professioneller Hersteller von Brauereianlagen und Edelstahlbehältern produzieren wir derzeit ein Großprojekt für einen Lagertank aus Stahl. Dieser Auftrag umfasst 15 Einheiten eines 80-Tonnen-Edelstahl-Lagertanks, der mit einem Rührwerk ausgestattet ist. Diese Lagertanks bieten eine sichere und effiziente Lagerung von Materialien in großem Maßstab und helfen den Kunden, den wachsenden Produktionsbedarf zu decken.

Höhepunkte des Projekts

- Große Kapazität: Jeder Fermenter hat ein effektives Volumen von 80 Tonnen und erfüllt damit die Anforderungen des Kunden an eine groß angelegte kontinuierliche Fermentation.

- Hochwertiges Material: Der Tankkörper ist aus 12 mm dicken, hochwertigen Edelstahlplatten gefertigt, die eine lange Lebensdauer und Korrosionsbeständigkeit gewährleisten.

- Wissenschaftlicher Aufbau: Mit einer Tankhöhe von 13 Metern und einem Innendurchmesser von 3,4 Metern optimiert die Konstruktion die Durchmischung, die Wärmeübertragung und den Gasaustausch während der Gärung.

- Strenge Handwerkskunst: Die Tanks werden nun geschweißt und isoliert. Die automatische Schweißtechnik von T+P sorgt für glatte, starke und druckfeste Schweißnähte. Die äußere Isolierschicht garantiert eine stabile Temperaturkontrolle und verbessert die Energieeffizienz und Produktkonsistenz.

Merkmale & Edelstahl-Speichertank

Unser Lagertanks aus rostfreiem Stahl sind so konstruiert, dass sie die höchsten Standards in Bezug auf Haltbarkeit, Sicherheit und Effizienz erfüllen, was sie ideal für Branchen wie Brauereiwesen, Biochemie, Lebensmittelverarbeitung und Produktion macht. Jeder Tank ist aus hochwertigem Edelstahl gefertigt, was eine außergewöhnliche Korrosionsbeständigkeit, einfache Reinigung und lange Lebensdauer auch unter anspruchsvollen Bedingungen gewährleistet.

Die wichtigsten Merkmale sind:

Große Kapazität: Erhältlich in kundenspezifischen Mengen bis zu 80 Tonnen oder mehr, die eine kontinuierliche Großproduktion unterstützen.

Hochwertiges Material: Konstruiert aus dicken Edelstahlplatten, um Stärke, Hygiene und die Einhaltung der Industrievorschriften zu gewährleisten.

Optimierte Struktur: Die optimierten Abmessungen sorgen für eine effiziente Mischung, Wärmeübertragung und stabile Druckleistung.

Fortschrittliche Schweißtechnik: Das automatische Schweißen von T+P garantiert glatte, starke und leckfreie Schweißnähte.

Thermische Isolierung: Externe Isolierschichten sorgen für eine präzise Temperaturkontrolle und verbessern die Energieeffizienz und die Produktkonsistenz.

Mit diesen Vorteilen steigern unsere Lagertanks aus Edelstahl nicht nur die Produktionseffizienz, sondern sichern auch die Produktqualität, was sie zu einer zuverlässigen Wahl für industrielle Anwendungen macht.

Fortgeschrittene automatische Edelstahl-Container-Verarbeitungsanlagen

METO verfügt über hochmoderne automatisierte Verarbeitungsanlagen, darunter Maschinen zum Glätten von rostfreiem Stahl, automatische Blechwalzmaschinen, automatische Kegelwalzmaschinen, automatische Laserschweißmaschinen, automatische Laserschneidmaschinen, automatische Rundnahtschweißmaschinen, automatische Längsnahtschweißmaschinen, große CNC-Bearbeitungsmaschinen, Laserschneid- und Schweißmaschinen-Arbeitsplätze, automatische Konstanttemperatur-Schäummaschinen, automatische Poliermaschinen, CNC-Biegemaschinen.

Fortschrittliche Laserschweißtechnik

METO bietet eine Vielzahl von lasergeschweißten Ummantelungen an, darunter Dimple Jackets, Corrugated Channel Jackets und Arch Channel Jackets.

Im Vergleich zum herkömmlichen Mantelschweißen haben die lasergeschweißten MaiTuo-Mäntel folgende Vorteile:

- Hohe Präzision beim Schweißen

Dank des kleinen Laserpunkts und der hohen Energiedichte ist die Schweißnaht schmal und genau positioniert, was präzise Mantelabmessungen und eine hervorragende Abdichtung gewährleistet. - Minimale hitzebeeinflusste Zone

Verringert die thermische Schädigung des Grundmaterials erheblich, wobei die mechanische Festigkeit und die Korrosionsbeständigkeit des Mantels erhalten bleiben, wodurch die Lebensdauer und die Zuverlässigkeit verlängert werden. - Hohe Schweißgeschwindigkeit

Mit einem hohen Automatisierungsgrad verbessert das Laserschweißen die Konsistenz und Stabilität, verkürzt die Fertigungszyklen und reduziert die Gesamtkosten. - Hohe Druckbeständigkeit

Die Schweißnähte zeichnen sich durch eine starke Verschmelzung und eine hervorragende Abdichtung aus, wodurch das Risiko von Leckagen oder Brüchen minimiert wird. Einige Produkte können einem Druck von bis zu 50 bar standhalten. - Ausgezeichnetes Erscheinungsbild

Die Schweißnähte sind glatt und flach und erfordern nur wenig Nachbearbeitung. Dies ist besonders wertvoll für Produkte mit strengen Anforderungen an das Aussehen und verbessert die allgemeine Wettbewerbsfähigkeit auf dem Markt.

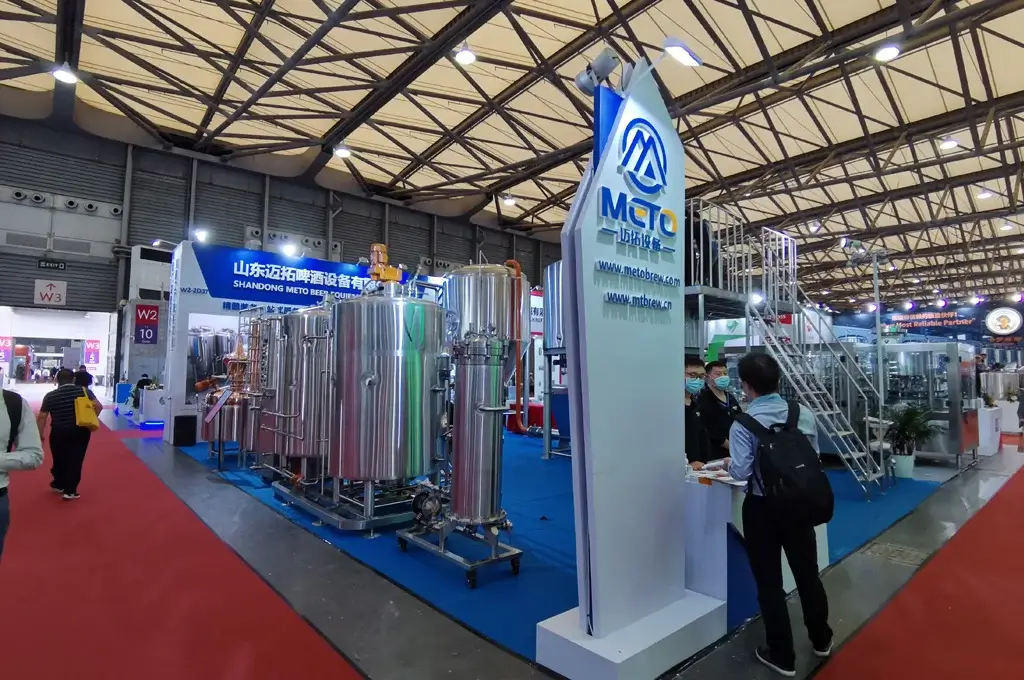

Wenn Sie auch an unseren Fermentationsanlagen interessiert sind, wenden Sie sich bitte an Kontaktieren Sie uns Meto Ausrüstung. Wir empfehlen Ihnen die für Ihre Bedürfnisse am besten geeignete Brauereiausrüstung und bieten Ihnen die umfassendsten und hochwertigsten Dienstleistungen.