中国啤酒酿造设备制造商

METO 精酿啤酒设备以其可靠的质量、卓越的性能和优质的服务赢得了国内外众多客户的认可。我们可以为您提供高质量的精酿啤酒设备。

全球高端酿酒设备供应商

500L 啤酒厂设备优势

500L 精酿啤酒设备系统使中小型企业家能够以相对较低的投资、灵活的操作和生产各种独特啤酒的能力进入精酿啤酒市场。

理想的商业规模和灵活性

这种输出方式非常适合小型手工啤酒厂、啤酒馆或大型酒吧。它既能为商业销售提供足够的产量,又能让酿酒师灵活地分批生产不同风格的啤酒(如 IPA、黑啤、小麦啤酒),避免了单一大批量生产造成库存过多的风险。

模块化设计

储罐、管道和平台采用模块化组合设计,并配有快速连接装置,可快速

安装。人性化设计,操作更简单。维护方便,降低维护成本。提供可扩展接口,满足设备升级需求。

用户界面友好,易于控制

对于正在向专业或职业酿酒师过渡的有经验的家庭酿酒师来说,500 升系统中的热交换、泵送和温度控制等过程比大型设备更直观、反应更灵敏。这样就能对酿造过程进行更精细的控制,确保每一批酒的质量。

全面的功能和完整的流程

标准的 500L 系统通常集成了醪槽、酸洗槽、煮沸釜和漩涡池,通常还包括一个自动 CIP(原位清洁)系统。这意味着从研磨到预发酵的所有关键过程都可以在一个系统内完成,无需额外的传送步骤。

确保质量和一致性

现代 500L 系统通常配备有精确的自动控制系统(如 PLC),可精确管理糖化和煮沸温度。这种可重复的精度是确保啤酒风味稳定和批次间一致性的关键,有助于建立可靠的品牌声誉。

500 升酿酒设备配置

Meto 的微型酿酒设备是酿酒厂、酒窖、餐馆、酒吧、酒店和小型酿酒厂的理想选择。它具有处理速度快、操作简便、质量一流和使用寿命长的特点。投资可在 1 - 2 年内全部收回。

麦芽粉碎装置

Ave.麦芽产量:200-300 公斤/小时

标准料斗可容纳 12 公斤麦芽

盖子和框架材料:不锈钢

- 双辊破碎机 1000kgs/h

- 柔性蛟龙或挠性蛟龙可直接将碾磨过的谷物提升到醪槽中

- 带水合器的谷物料斗

酿酒装置

- 2/3/4/5 容器,3 容器组合 醪液 烧煮釜 漩涡工艺

发酵装置

- 水箱容量:500 升(最小水头空间:+25%)

- 外壳SUS304 全焊接;TH=2 毫米

- 隔热材料:TH=80毫米,低导热聚氨酯

- 内部全面抛光至 0.4 μm,无死角

- 储罐和夹套工作压力:< 0.2Mpa

乙二醇冷却装置

- 乙二醇水箱

- 乙二醇冷水机

- 乙二醇水输送(泵和管线)

CIP 单元

- CIP 移动泵

- CIP 购物车

- CIP 站

电源控制装置

- PID 控制柜

- 用于选配的 PLC 控制柜

- 半自动或全自动酿酒车间和发酵过程

项目应用

微型酿酒厂

2 个酿酒槽

啤酒屋或餐厅酿造系统

3 个酿酒槽

啤酒研发实验室

3 个酿酒槽

教育与培训中心

组合式 3 瓶啤酒酿造室

酿造体验场所

2 个酿酒槽

小型展览或临时生产基地

2 个酿酒槽

500 升酿酒设备参数

| 模型 | MT-500L |

| 容量 | 500 升/批 |

| 酿造/日 | 1-2 |

| 组合方法 | 醪槽,烧煮槽,反应釜/漩涡槽 |

| 应用 | 餐厅、酒吧、酒店、酿酒厂 |

| 加热方式 | 电加热/蒸汽加热/直火加热 |

| 电压 | 220 伏/380 伏或定制 |

| 酿酒师 | 1 |

| 高度 | >2.5m |

| 地区要求 | >45M² |

| 自动化程度 | 手动/半自动/全自动 |

寻找酿酒设备制造商?

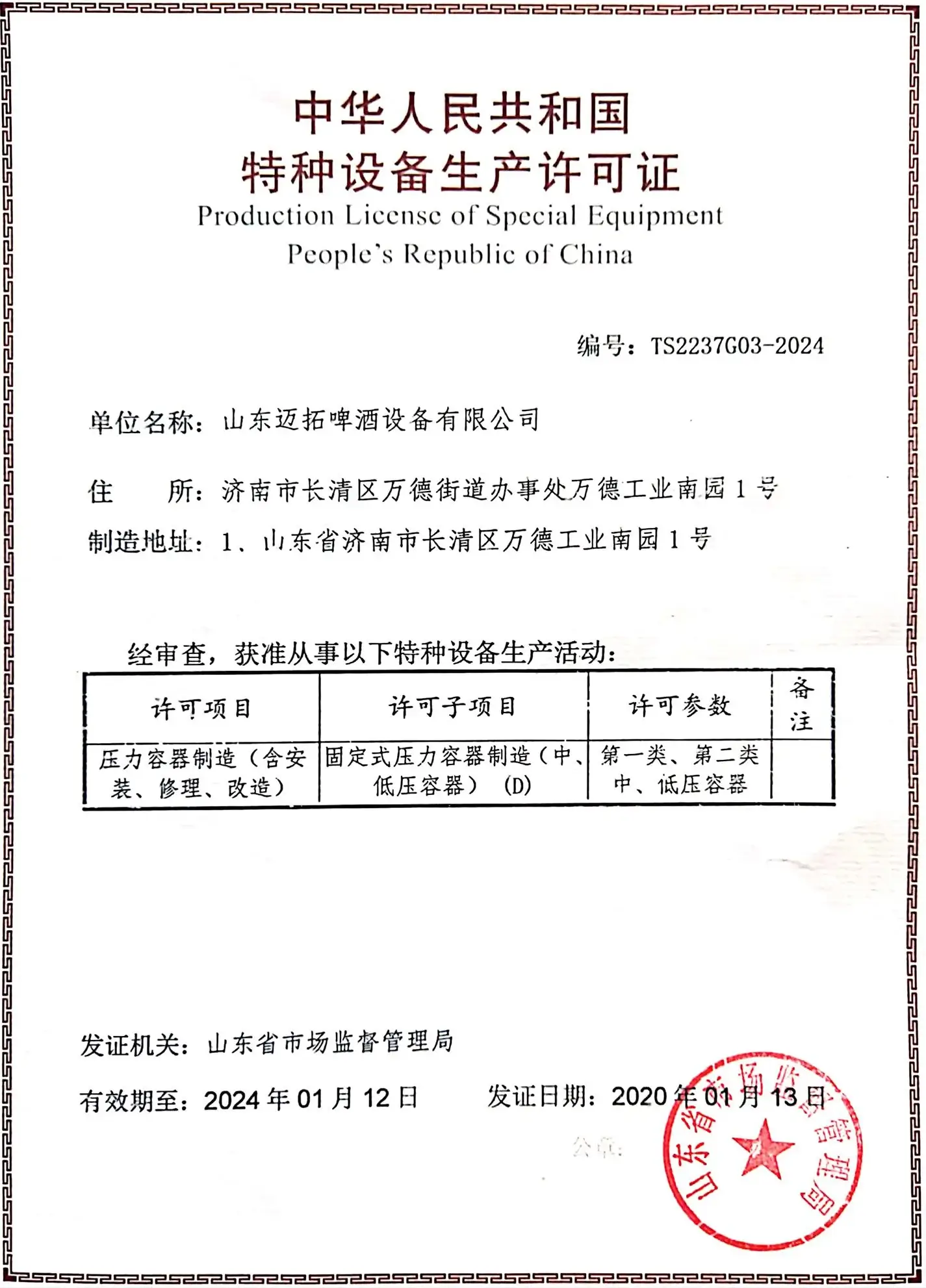

我们的认证

从 METO 获取工艺酿造解决方案!

咨询专家

如果您想建立自己的梦想酿酒厂,请联系我们。我们有专业的工程师和销售人员为您解答所有问题。