热销产品

100L Brewery Equipment

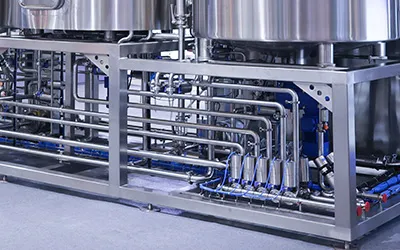

- Compact brewhouse with precise automatic temperature control, perfect for pilot brewing and small-scale production.

- High wort clarity and stable extraction efficiency with optimized lautering and whirlpool system.

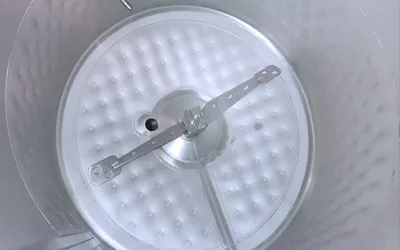

- Professional welding: outer weld and inner melt with acid passivation for smooth, corrosion-resistant interiors.

- Dual-layer stainless steel design with glycol water jacket, pressure rated up to 3 bar for safe and efficient brewing.

- 24/7 Professional Support with Free 2D/3D Drawings and Custom Layout Solutions

- Safeguarding Your Investment – Reliable Equipment and Long-Term Service Commitment

Leading Brewery Equipment Manufacturer In China

We are a trusted brewery equipment manufacturer in China, serving craft brewers and beer brands worldwide. With EU CE certification, advanced technology, and proven experience, we deliver reliable, efficient, and safe brewing solutions. From design to after-sales service, we help you build and grow your dream brewery with confidence.

Quality Control

Custom Design

端到端支持

经济高效

Fast Delivery

100L Brewery Equipment Advantages

"(《世界人权宣言》) 100L brewery system is compact, efficient, and durable — perfect for pilot brewing, recipe testing, and small-scale production. It delivers professional quality with easy operation, making it the smart choice for startups and innovation.

Brew Smarter, Not Harder

- Optimized Production Capacity:The 100L batch size is ideal for pilot brewing, recipe development, and small-scale production. With an annual capacity of up to 14T–30T, it perfectly suits brewpubs, restaurants, and startups looking to validate new recipes or launch limited-edition beers.

- Energy and Cost Efficiency:Compact design with premium insulation reduces heat loss by 30%, while multiple heating options (electric, steam, or gas) ensure flexibility and energy savings. Smart temperature control technology lowers energy consumption by more than 15%, making it a cost-effective entry into professional brewing.

- Consistent Quality Assurance:Precision temperature control within ±0.5°C guarantees stable brewing results, even for experimental batches. Constructed with food-grade SUS304 stainless steel and mirror-polished surfaces, it meets strict hygiene standards and provides long-lasting durability.

- Ease of Operation and Maintenance:The intuitive PLC or semi-automatic interface allows easy recipe adjustment and repeat brewing. Integrated CIP (Clean-in-Place) system reduces cleaning time by nearly 50%, ensuring higher efficiency and simplified maintenance for small teams.

100L Brewery Equipment Configurations

For 100L microbrewery equipment configurations, we focus on tailored solutions. We adjust every detail of the setup based on customers’ specific circumstances, including available site area, investment budget, and production targets, to provide equipment that perfectly matches their brewing operations and supports smooth production.

主要系统

100L Brewery Equipment Parameters

| 模型 | MT-100L |

| 容量 | 100L/Batch |

| 酿造/日 | 1 |

| 组合方法 | 2 vessels : Mash tun/Lauter tun, Kettle/whirlpool tank |

| 应用 | 餐厅、酒吧、教育中心、微型酿酒厂 |

| 加热方式 | 电加热/蒸汽加热/直火加热 |

| 电压 | 交流 380/220 伏,50/60 赫兹 |

| 酿酒师 | >1 |

| 高度 | >2m |

| 地区要求 | > 10m2 |

| 自动化程度 | Manual / Semi-automatic |

FAQ of 100L Brewery Equipment

Q1: What is the typical application of a 100L brewery system?

A: The 100L system is mainly used for pilot brewing, recipe testing, small-scale production, and educational brewing labs. It’s also ideal for brewpubs, restaurants, and startups entering the craft beer market.

Q2: How much beer can I produce with a 100L system?

A: Each batch yields about 80–90L of finished beer, depending on the recipe and brewing process. On an annual basis, the capacity can reach 14T–30T if brewing regularly.

Q3: What heating options are available?

A: The system supports electric, steam, or direct gas heating, offering flexibility according to your space, budget, and energy availability.

Q4: Is the 100L system easy to operate?

A: Yes. It comes with a manual or semi-automatic control system, precise temperature control. Even beginners can operate it with minimal training.

Q5: How about installation and training?

A: METO provides detailed layout design, technical drawings, and 3D sketches. We also offer free online guidance for installation, operator training, and maintenance support.

Q6: What is the warranty period?

A: All tanks are covered by a 6 年保修, while auxiliary machines and accessories have a 1-year warranty, plus additional free spare parts.

Q7: Can the system be expanded later?

A: Yes. The modular design allows you to add more fermenters, bright tanks, or auxiliary machines as your production grows.

Looking For a Nano Brewery Equipment ?

Factory Environment

Safe, successful pre-assembly delivery

What our clients say?

Request an Instant Quote for Your Project!

如果您想建立自己的梦想酿酒厂,请联系我们。我们有专业的工程师和销售人员为您解答所有问题。