中国のビール醸造設備メーカー

METOのクラフトビール設備は、確かな品質、優れた性能、優れたサービスにより、国内外で多くのお客様に認められています。高品質なクラフトビールをご提供いたします。

世界の高級醸造設備プロバイダー

500L 醸造設備の利点

500Lクラフトビール設備システムは、中小規模の起業家が、比較的低額な投資で、柔軟な運用が可能で、幅広い種類のユニークなビールを製造できるクラフトビール市場に参入することを可能にする。

理想的な商業規模と柔軟性

この出力は、小規模なクラフトビール醸造所、ブルーパブ、または大規模なバーに最適です。商業販売に十分な量を提供する一方で、醸造者は異なるビールスタイル(例えば、IPA、スタウト、小麦ビール)を別々のバッチで製造する柔軟性を持つことができ、1つの大きなバッチから過剰在庫のリスクを避けることができます。

モジュラー設計

タンク、パイプライン、プラットフォームは、迅速な接続のためのクイックフィットを備えたモジュラーコンビネーションとして設計されています。

設置が簡単です。人間化された設計、より簡単な操作。便利なメンテナンス、メンテナンスコストを削減します。拡張可能なインターフェイスを提供し、機器のアップグレードのニーズを満たします。

ユーザーフレンドリーでコントロールが容易

プロやプロの醸造家に移行する経験豊富な自家醸造家にとって、500Lシステムの熱交換、ポンピング、温度制御などのプロセスは、大型のセットアップよりも直感的で反応が良い。これにより、醸造プロセスをより細かく制御することができ、各バッチの品質を確保することができます。

包括的な機能と完全なプロセス

標準的な500Lシステムには通常、マッシュ・タン、ローター・タン、ボイル・ケトル、ワールプールが統合されており、多くの場合、自動CIP(Cleaning-In-Place)システムも含まれている。これは、余分な移送ステップなしに、製麦から予備発酵までのすべての主要工程を1つのシステム内で完了できることを意味する。

品質と一貫性の確保

最新の500Lシステムには、多くの場合、正確な自動制御システム(PLCなど)が装備されており、マッシングとボイリングの温度を正確に管理しています。この再現可能な精度は、安定したビールの風味とバッチ間の一貫性を確保する鍵であり、信頼できるブランドの評判を築くのに役立ちます。

500L醸造設備構成

メト社の地ビール醸造設備は、ブルーパブ、タップルーム、レストラン、バー、ホテル、小規模醸造所にとって理想的な選択肢です。迅速な処理、簡単な操作、一流の品質、長い耐用年数が特徴です。投資は1~2年以内に完全に回収できる。

製麦ユニット

平均モルト能力:200-300kg/時

標準ホッパーは12kgのモルトを収納可能

カバー・フレーム材質:ステンレススチール

- 二重ローラークラッシャー 1000kgs/h

- フレキシブルオーガーまたはフレックスオーガーで、粉砕した穀物を直接マッシュタンに持ち上げる。

- ハイドレーター付き穀物ホッパー

醸造所ユニット

- 2/3/4/5ベッセル、コンビネーション3ベッセル マッシュ ローターケトル ワールプールプロセス

発酵ユニット

- タンク容量: 500L (最低ヘッドスペース: +25% )

- 外殻:SUS304 全溶接 TH=2mm

- 断熱材:熱伝導率の低いPUを使用したTH=80mm

- デッドコーナーのない0.4μmまで研磨された内部

- タンクとジャケットの使用圧力< 0.2Mpa

グリコール冷却ユニット

- グリコール水タンク

- グリコールウォーターチラー

- グリコール水移送(ポンプ&パイプライン)

CIPユニット

- CIP移動式ポンプ

- CIPカート

- CIPステーション

電源制御ユニット

- PIDコントロールキャビネット

- オプションのPLC制御キャビネット

- 醸造所と発酵プロセスの半自動または全自動

プロジェクト アプリケーション

マイクロブルワリー

2槽式醸造所

ブリューパブまたはレストラン用醸造システム

3容器醸造所

ビール研究所

3容器醸造所

教育研修センター

3槽式醸造所

醸造体験会場

2槽式醸造所

小規模な展示会または一時的な生産拠点

2槽式醸造所

500L醸造設備パラメータ

| モデル | MT-500L |

| 定員 | 500L/バッチ |

| ビール/日 | 1-2 |

| 組み合わせ方式 | マッシュタン、ラウタータン、ケトル/ワールプールタンク |

| 申し込み | レストラン、バー、ホテル、醸造所 |

| 加熱方法 | 電気暖房/スチーム暖房/直火暖房 |

| 電圧 | 220V/380Vまたはカスタマイズ |

| ブリューマスター | 1 |

| 高さ | >2.5m |

| エリアリクエスト | >45M² |

| 自動化の度合い | マニュアル / セミオート / フルオート |

醸造設備メーカーをお探しですか?

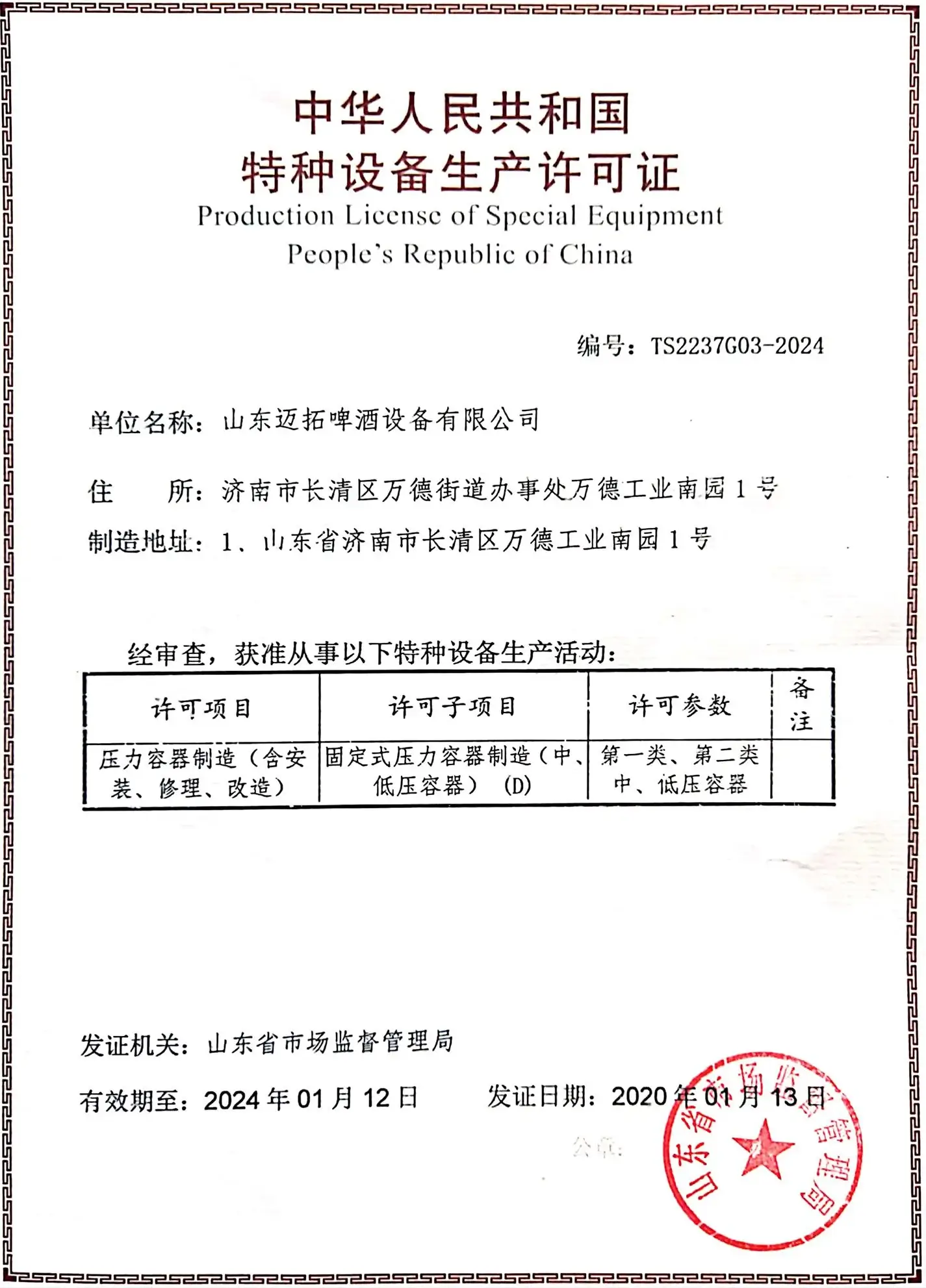

認定資格

クラフト・ブルーイング・ソリューションはMETOから!

専門家に相談する

夢の醸造所を開設したい方は、ぜひ弊社にご連絡ください。専門の技術者と営業スタッフがあらゆるご質問にお答えします。